- Admin

- #1

- Joined

- May 21, 2021

- Messages

- 1,864

- Reaction score

- 1,029

- Points

- 113

- Location

- Stuart, Florida

- Website

- themikephillipsforum.com

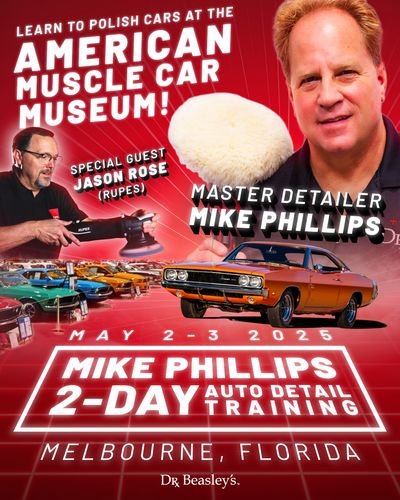

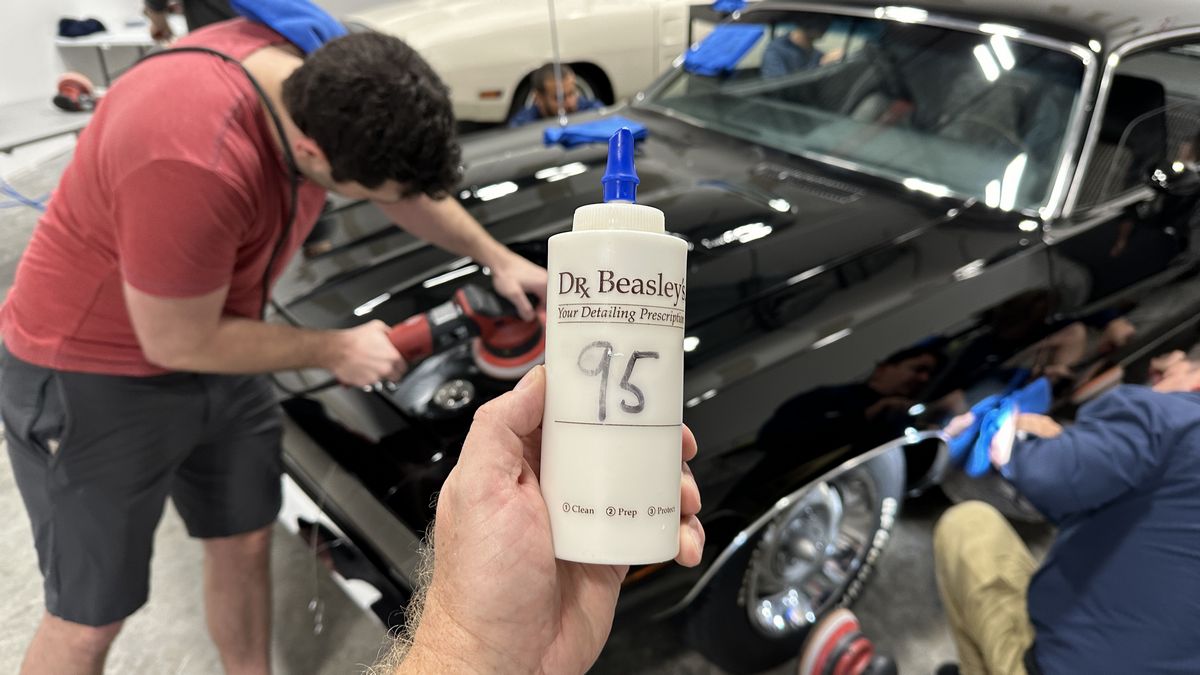

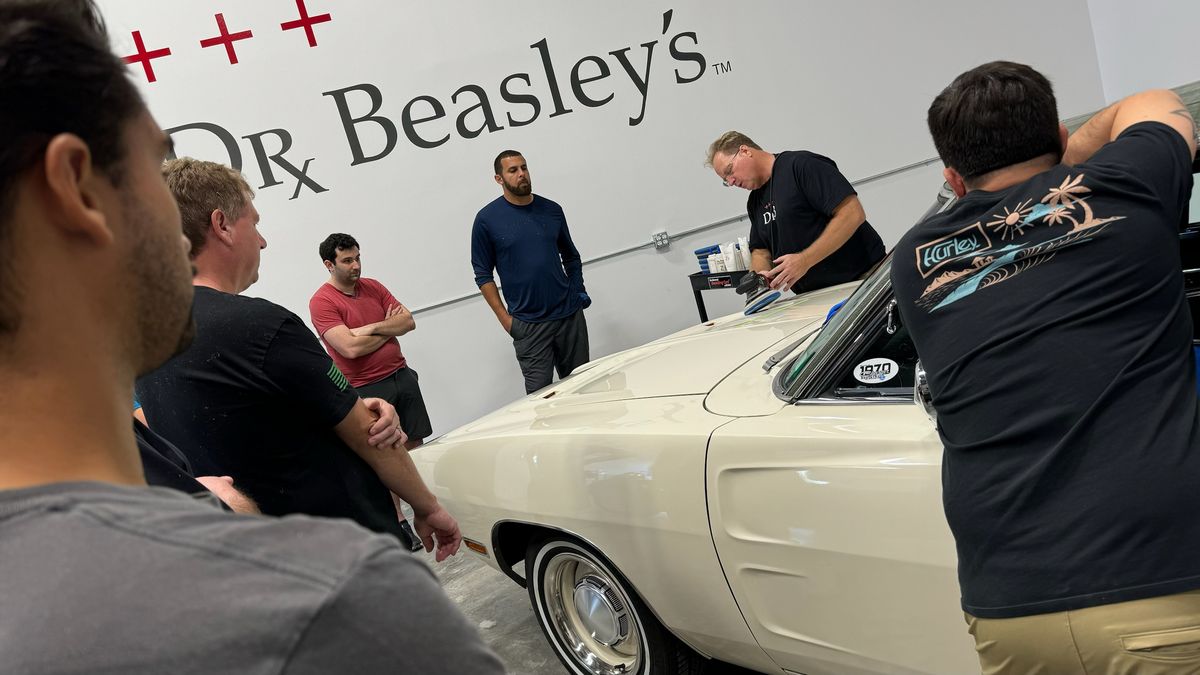

256 Pictures - January 20th 2024 1-Day Detailing Class at Dr. Beasley's in Stuart Florida

Fresh video sharing what you get to do in one of our classes.

January 20th, 2024 - 1 Day Paint Correction & Ceramic Coatings Class

4 cars for this class,

Day 1 - Friday Morning Session- Full Contact Wash

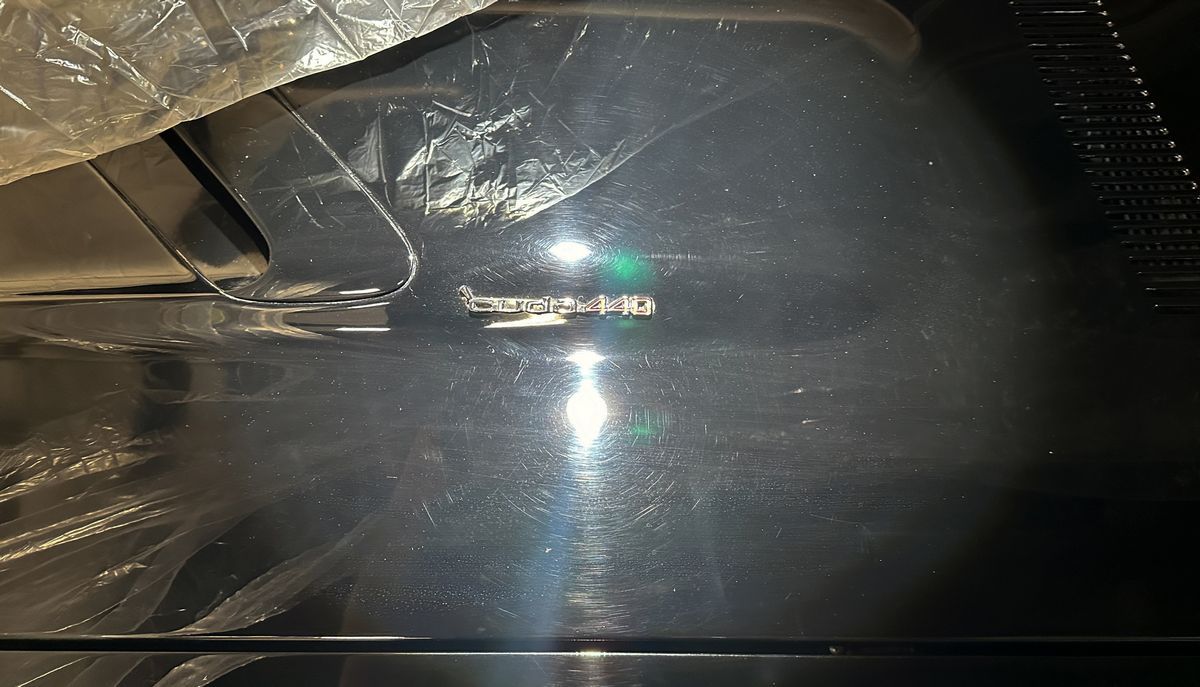

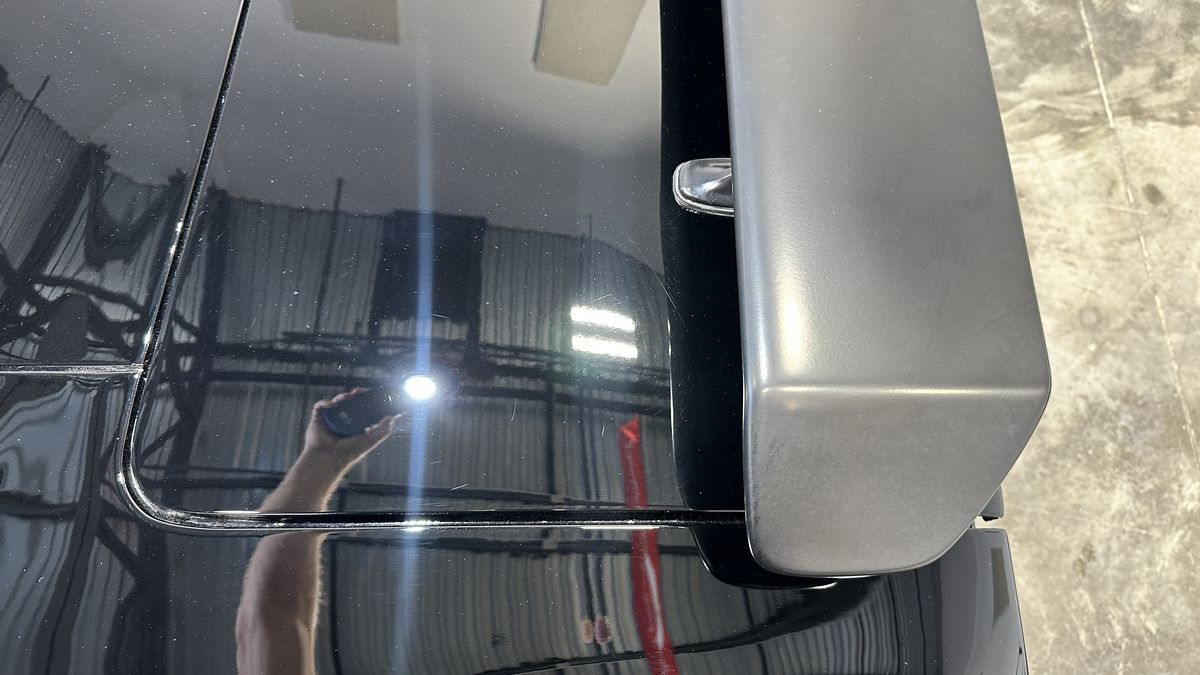

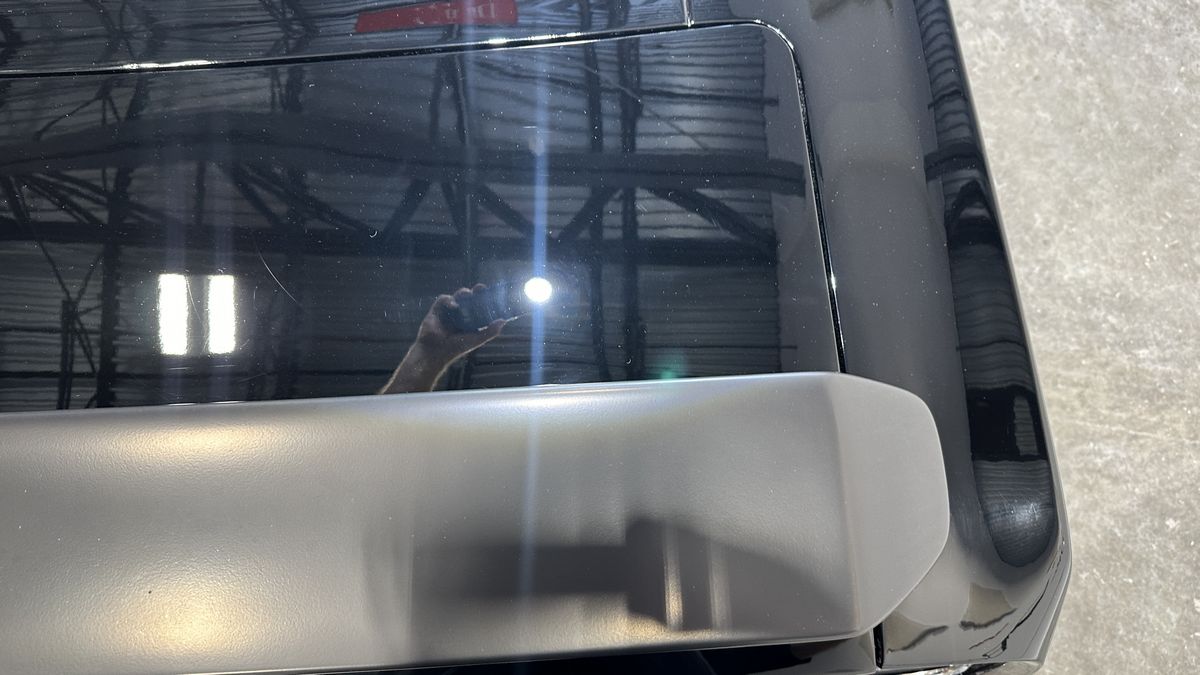

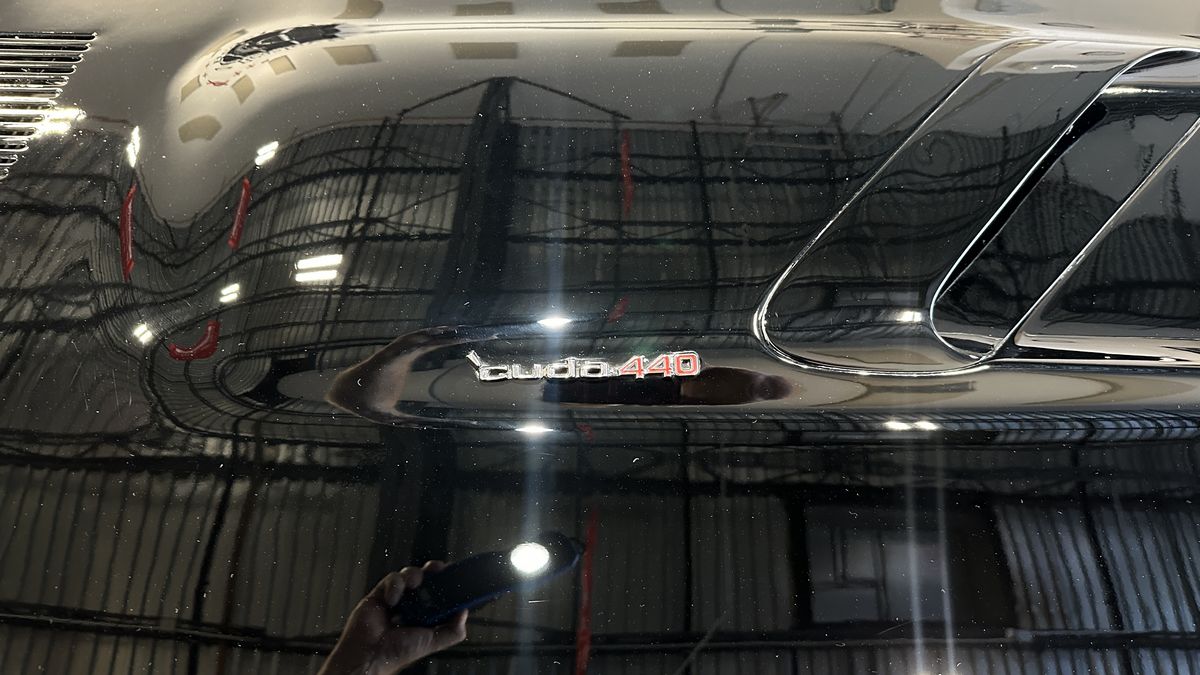

Normally I don't use running water to wash classic cars, but this car was so dirty and the tires really needed machine scrubbing, that we stated the morning off by getting the 440 Cuda washed and ready for paint correction.

And "yes" we start our classes early, (because there's so many topics to cover), and we start them ON TIME!

Mike

Fresh video sharing what you get to do in one of our classes.

January 20th, 2024 - 1 Day Paint Correction & Ceramic Coatings Class

4 cars for this class,

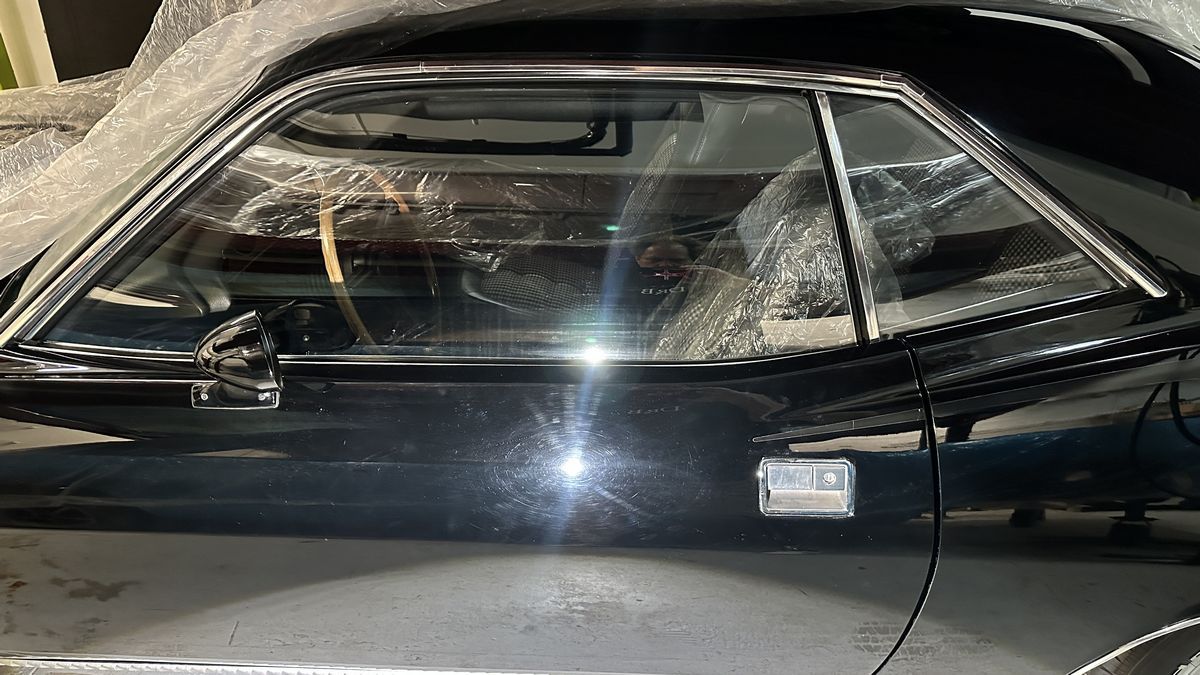

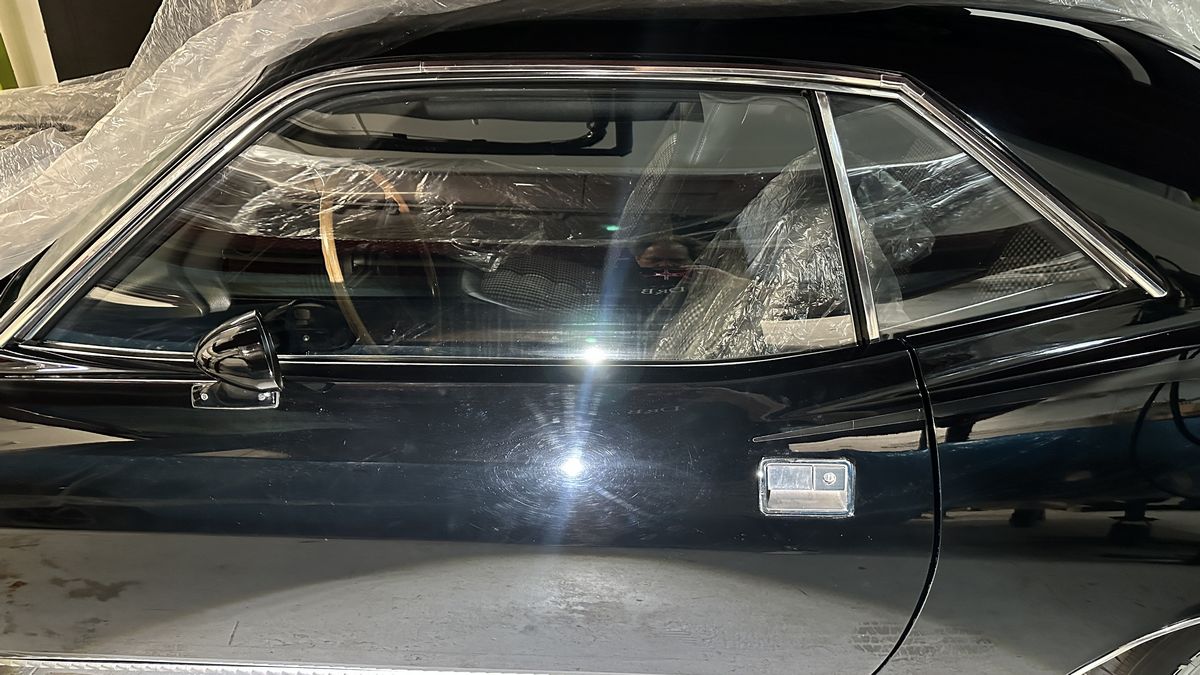

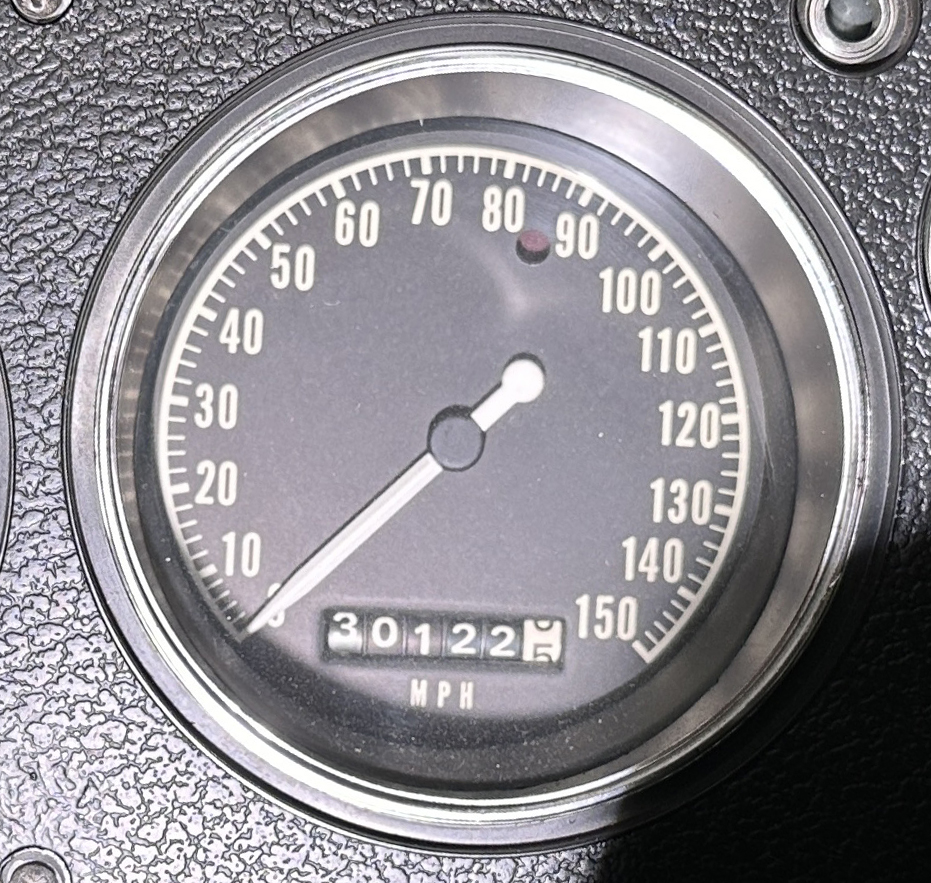

- 1970 Dodge Charger - 30,000 original miles

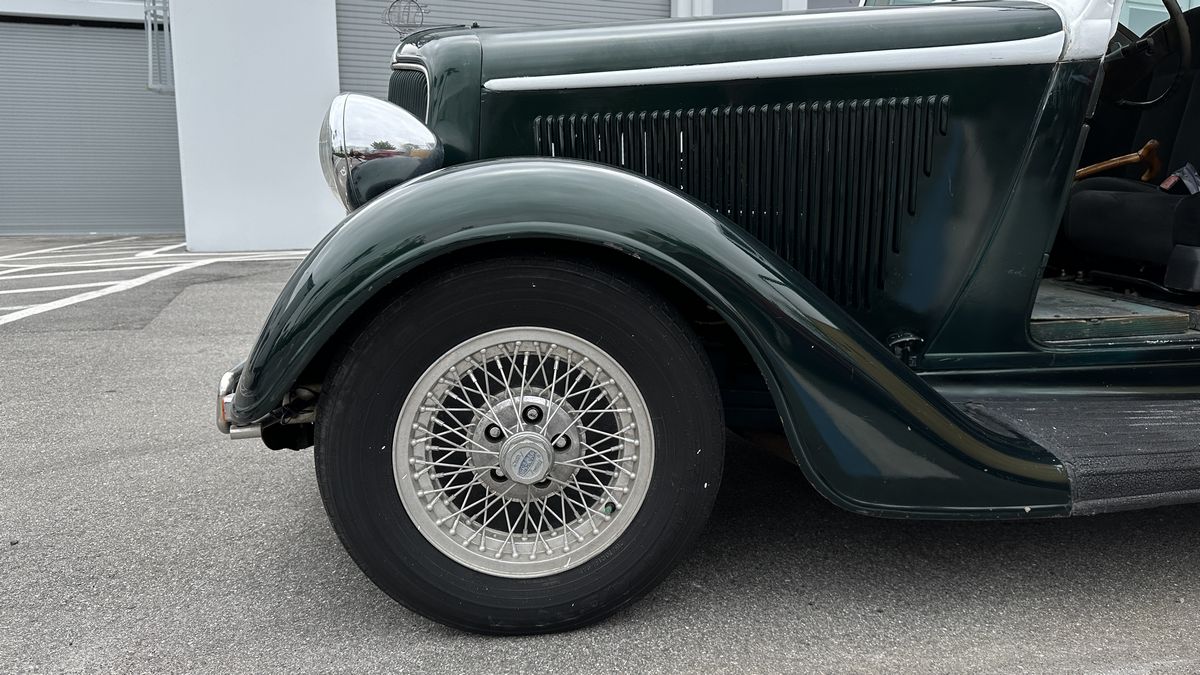

- 1934 Plymouth Streetrod - Dual Suicide Doors

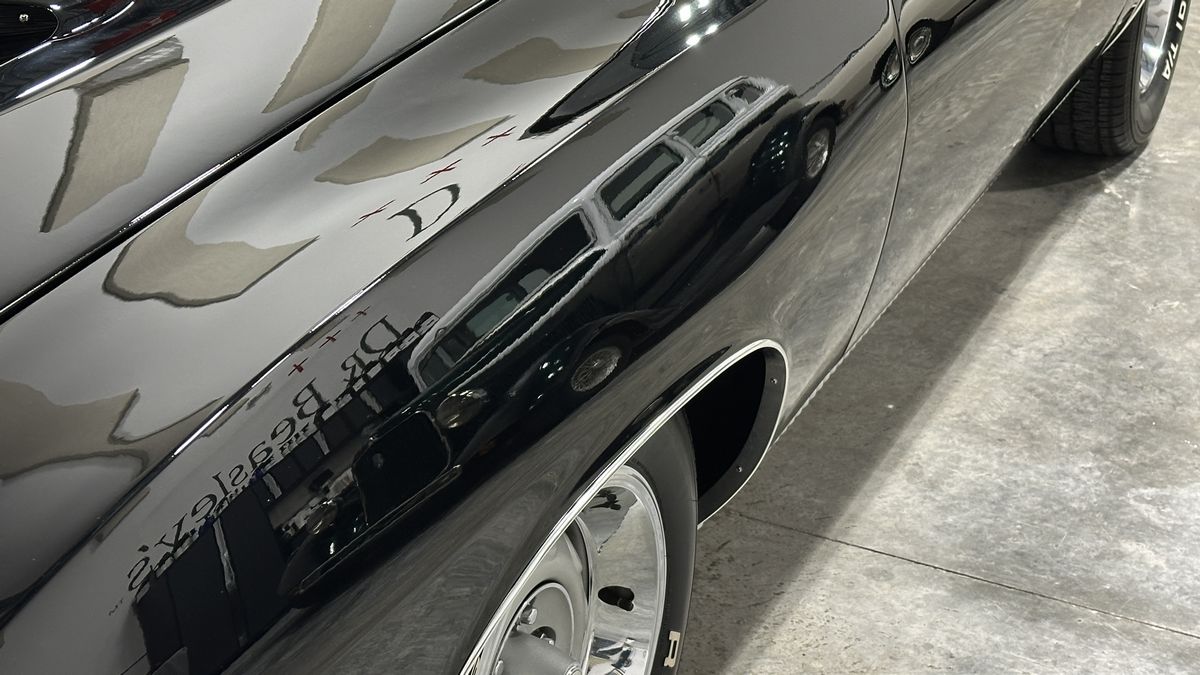

- 1970 Plymouth Cuda 440

- 2000 Honda CVR SUV

Day 1 - Friday Morning Session- Full Contact Wash

Normally I don't use running water to wash classic cars, but this car was so dirty and the tires really needed machine scrubbing, that we stated the morning off by getting the 440 Cuda washed and ready for paint correction.

And "yes" we start our classes early, (because there's so many topics to cover), and we start them ON TIME!

Mike

Last edited: