Mak

Member

Still working on the process and figuring out what works best. Had done the hood last year and a door and some other smaller spots since then. Yesterday I started on the trunk lid and surrounding side and top section on the rear of the car. The rear bottom has some significant scratches and needs done, but I ran out of abrasive discs so will tackle it another time.

I had to begin with 320 grit since the were some bad scratches here and there. Worked all the way up through 2000 grit film and then used some 3000 sunfoam discs I hadn’t used on the F100.

On the previous panels I got them looking significantly better than before I started, but that mirror finish is unforgiving, and I struggle to not have some random orbit micro scratches and pigtails. I spend so much time with each successive grit and making sure I’m removing all previous grit sanding scratches that I’m starting to think I’m introducing the micro scratches during the buffing and polishIng stages….

I work hard to try and keep everything clean and not introduce contaminates, but still suspect they are being done by my Flex Beast at the last stage. I sure don’t see and can’t find them prior….

I may start trying cheapo foam pads that I will just throw away after each use. I’ve got new scratching on the hood that I’ve noticed after several rounds of polishing the past year.

I‘m also wondering if the wool pad on a rotary is too aggressive after taking it all the way to 3000. Thinking about trying a microfiber or medium foam pad first, then following with the polishing pad on the random orbit at the end.

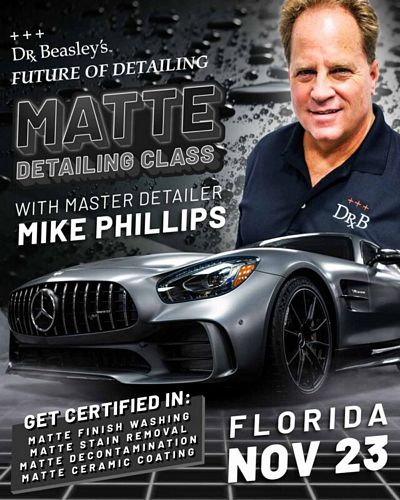

May also try my Porter Cable instead of the 3401 Beast, based on Mike’s last alum polishing article.

Hopefully my new pads arrive by Friday.

I had to begin with 320 grit since the were some bad scratches here and there. Worked all the way up through 2000 grit film and then used some 3000 sunfoam discs I hadn’t used on the F100.

On the previous panels I got them looking significantly better than before I started, but that mirror finish is unforgiving, and I struggle to not have some random orbit micro scratches and pigtails. I spend so much time with each successive grit and making sure I’m removing all previous grit sanding scratches that I’m starting to think I’m introducing the micro scratches during the buffing and polishIng stages….

I work hard to try and keep everything clean and not introduce contaminates, but still suspect they are being done by my Flex Beast at the last stage. I sure don’t see and can’t find them prior….

I may start trying cheapo foam pads that I will just throw away after each use. I’ve got new scratching on the hood that I’ve noticed after several rounds of polishing the past year.

I‘m also wondering if the wool pad on a rotary is too aggressive after taking it all the way to 3000. Thinking about trying a microfiber or medium foam pad first, then following with the polishing pad on the random orbit at the end.

May also try my Porter Cable instead of the 3401 Beast, based on Mike’s last alum polishing article.

Hopefully my new pads arrive by Friday.