- Admin

- #1

- Joined

- May 21, 2021

- Messages

- 1,680

- Reaction score

- 929

- Points

- 113

- Location

- Stuart, Florida

- Website

- themikephillipsforum.com

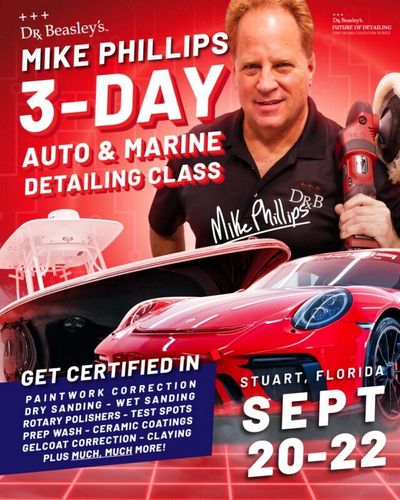

564 Pictures - May 3-day class at Dr. Beasley's O.R. in Stuart Florida with Mike Phillips

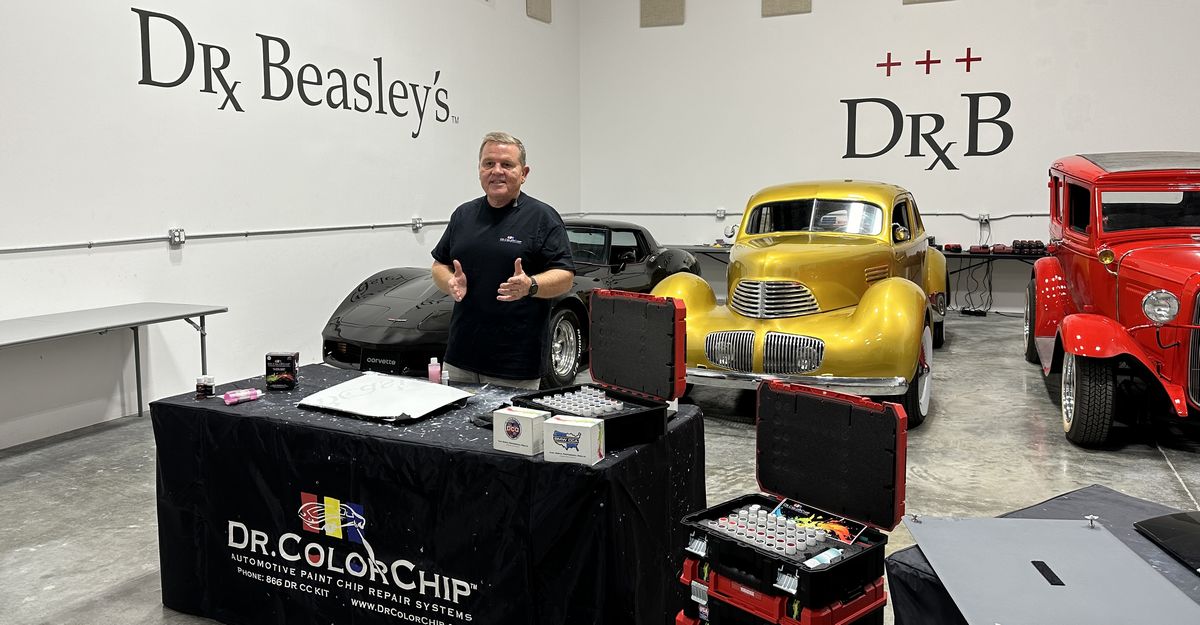

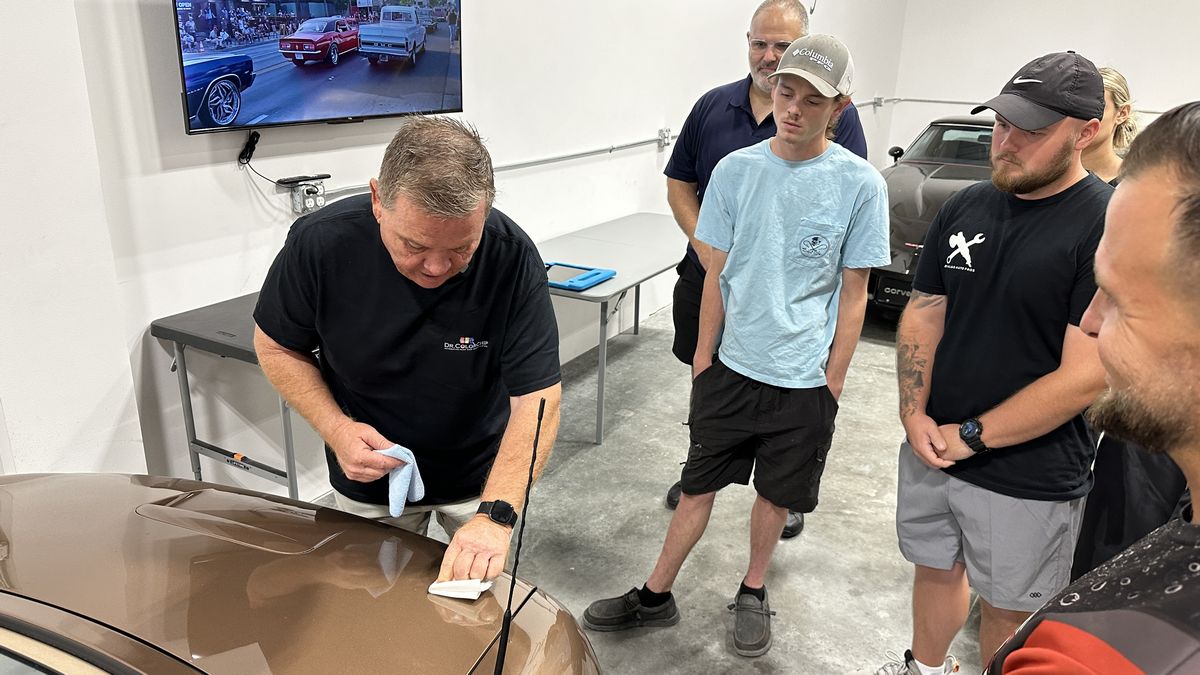

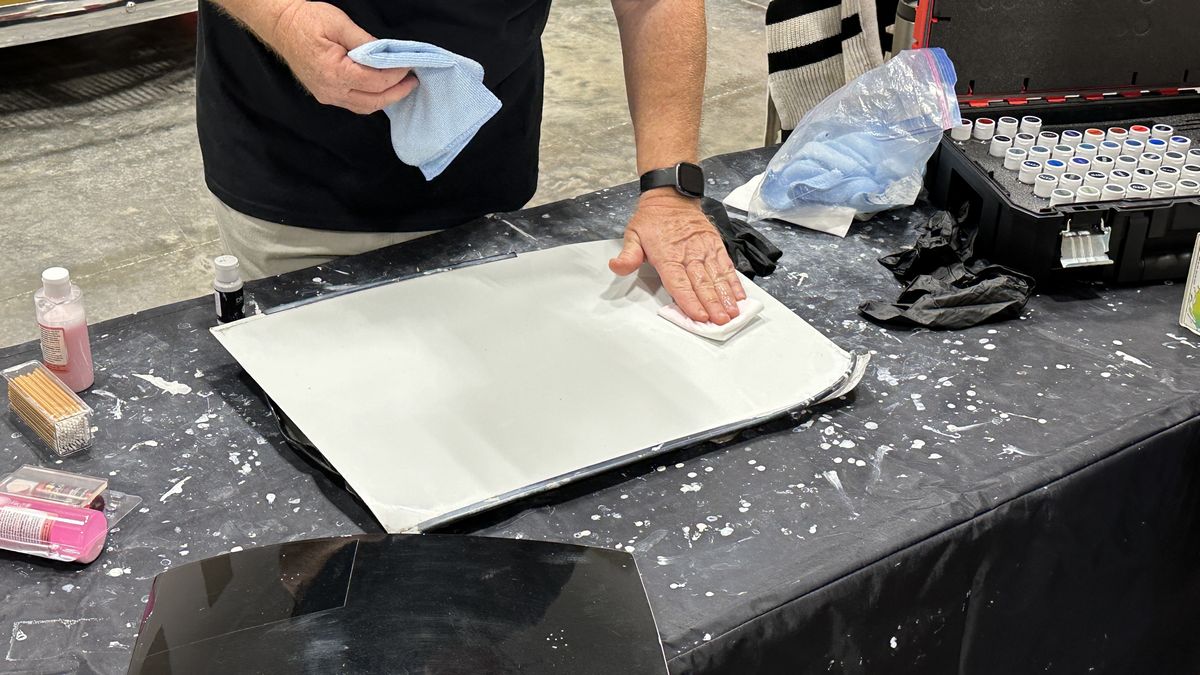

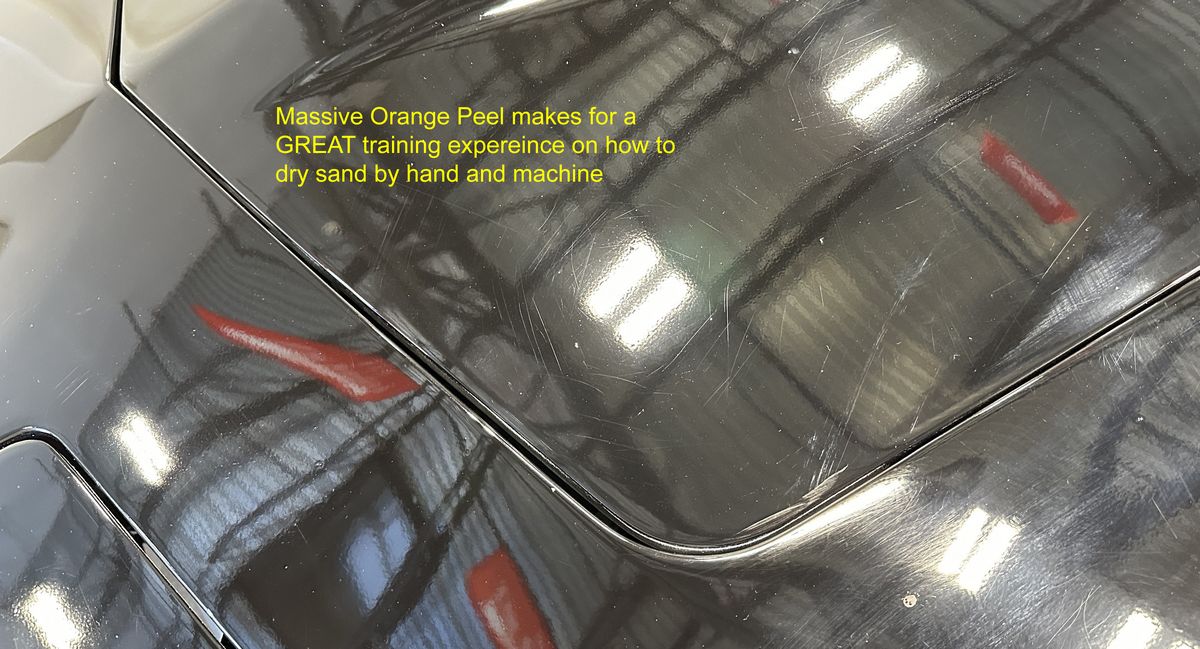

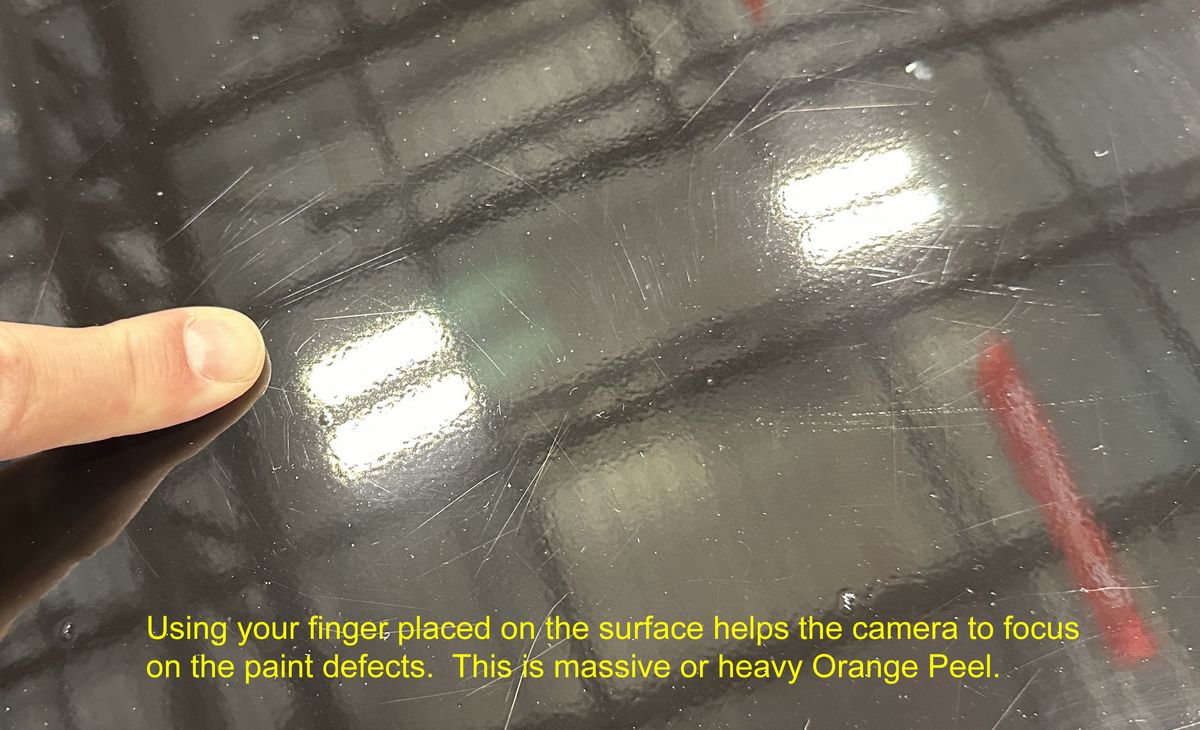

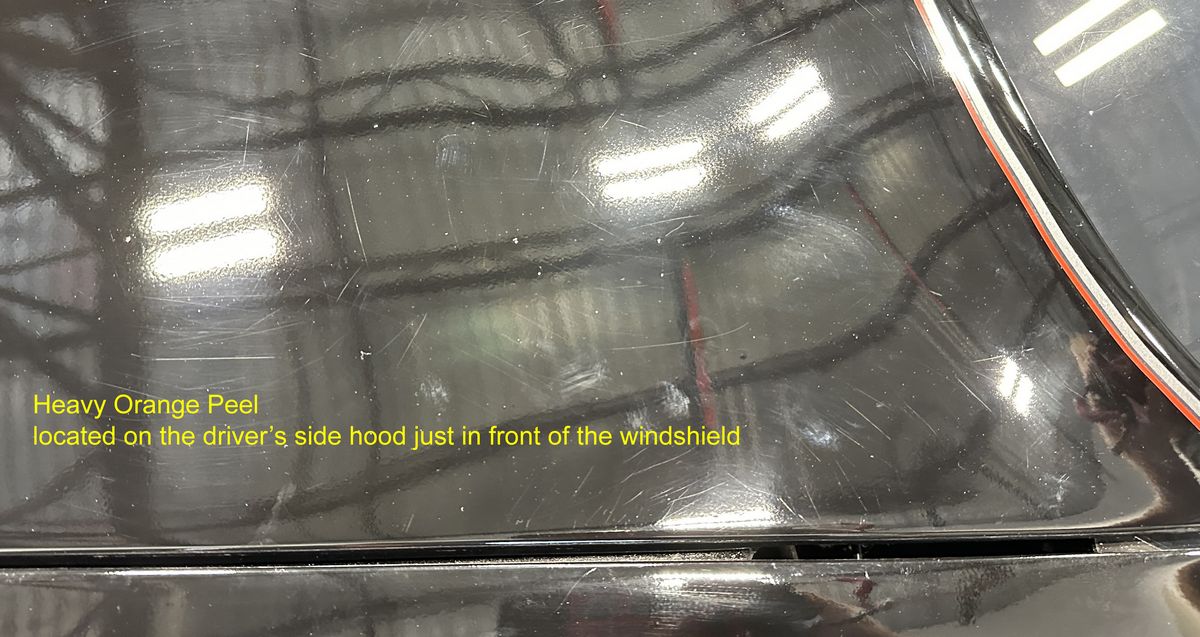

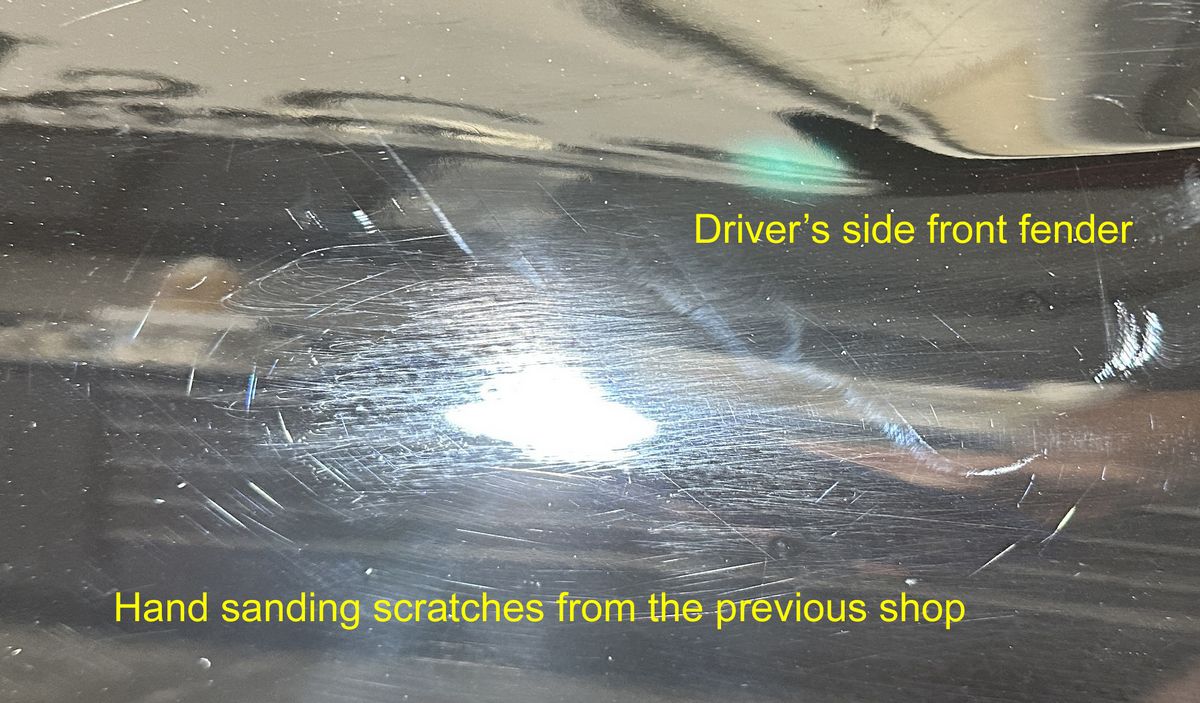

Congratulations to the May 3-day class! This class detailed 5 unique cars, including sanding 3 of these cars and also sanding, buffing and ceramic coating the 24' Robalo Center Console boat. To get signed up for the next big 3-day class that includes paint correction, ceramic coatings, sanding to remove orange peel and extreme boat detailing!

Click here to sign-up for the September 20th, 21st and 22nd NO chairs 100% hands-on detailing class!

Here's the class that made all the magic happen!

Kaiden

Michael

Tyler

Juan

Edson

Jesus

Shawn

Billy

Cory

Here's the 5 cars this class detailed and the huge center console boat

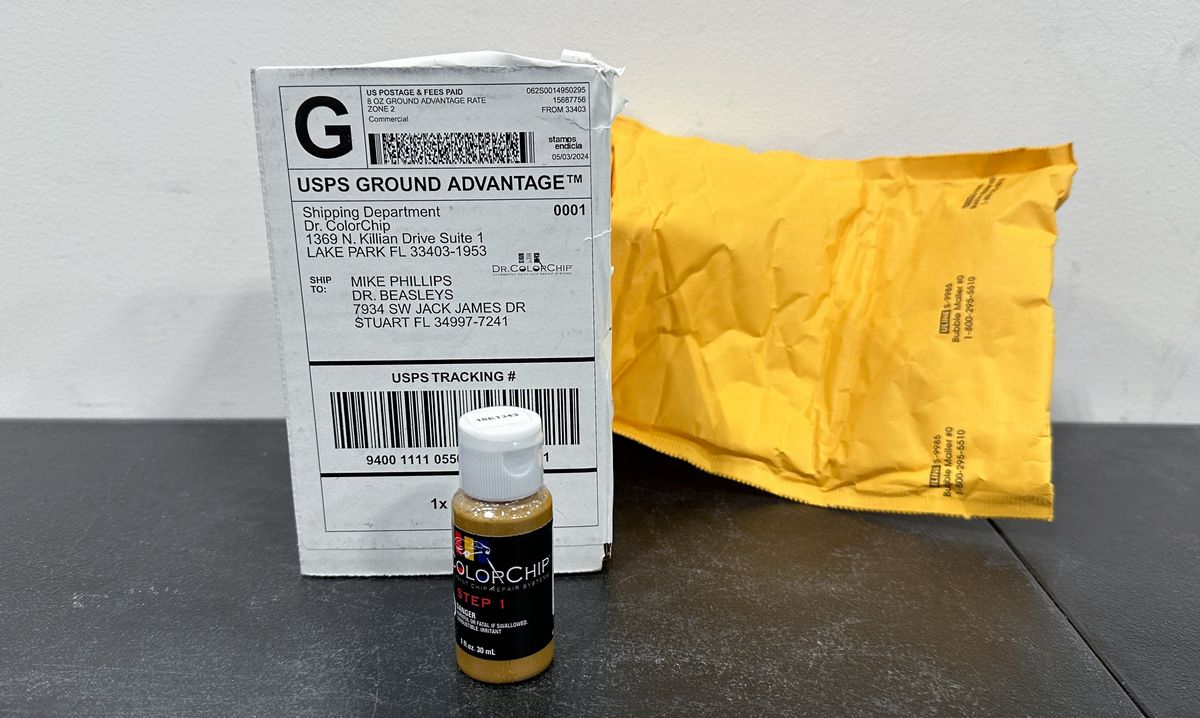

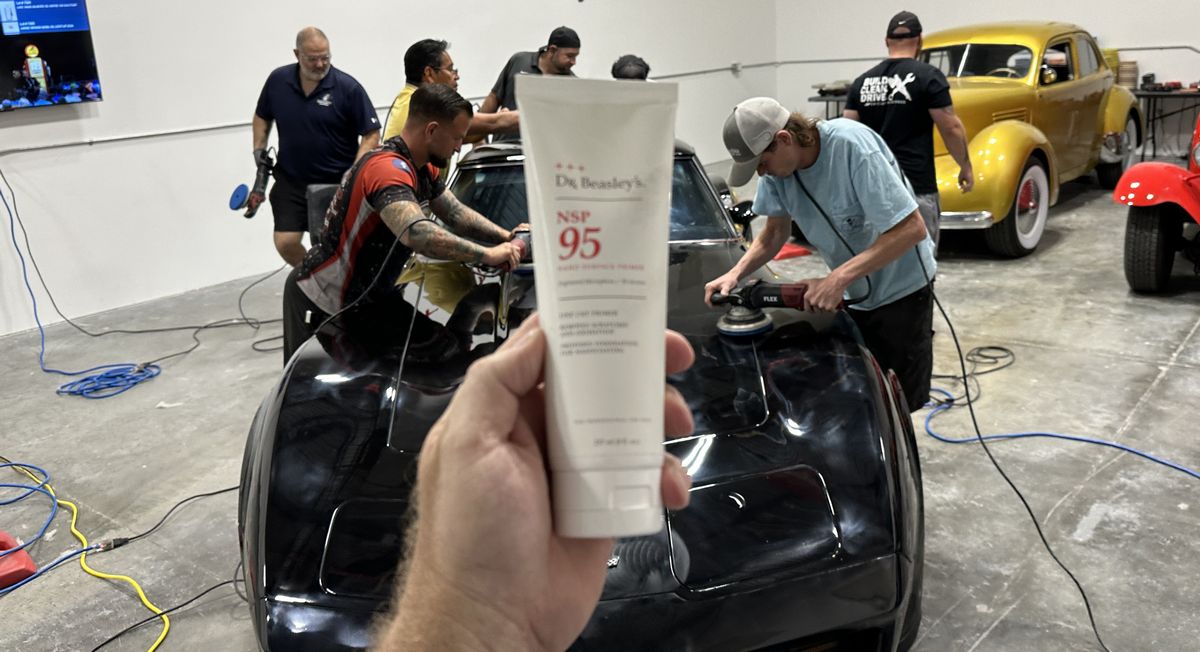

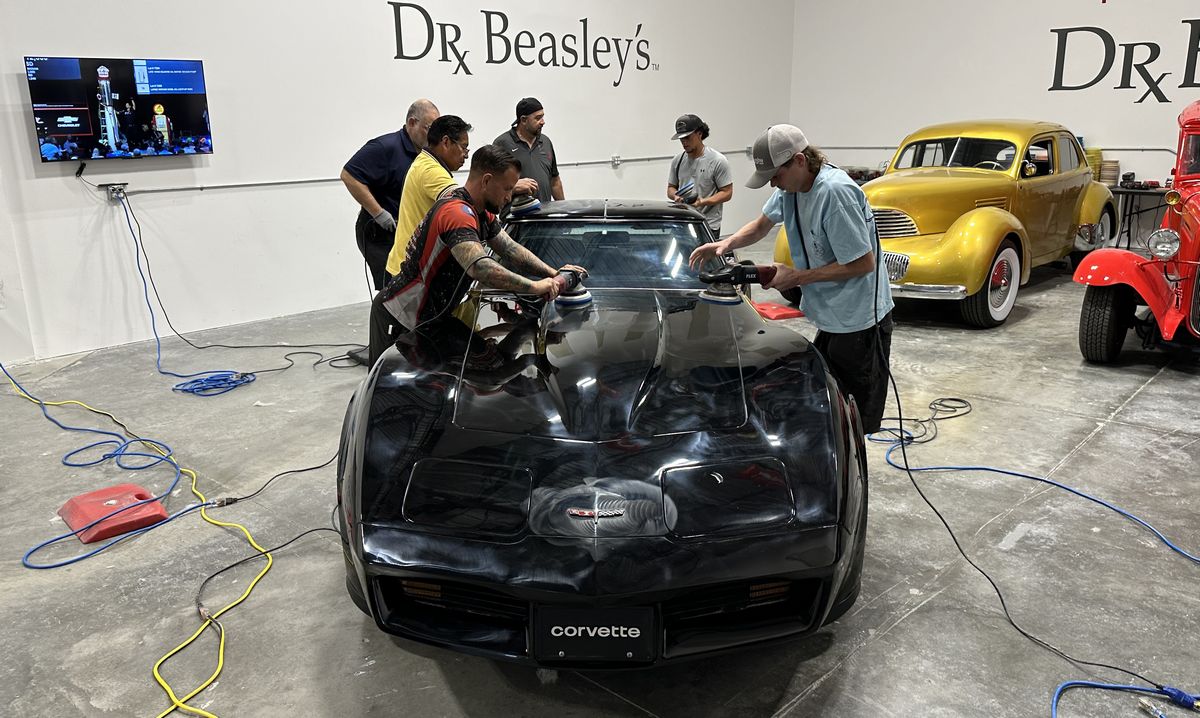

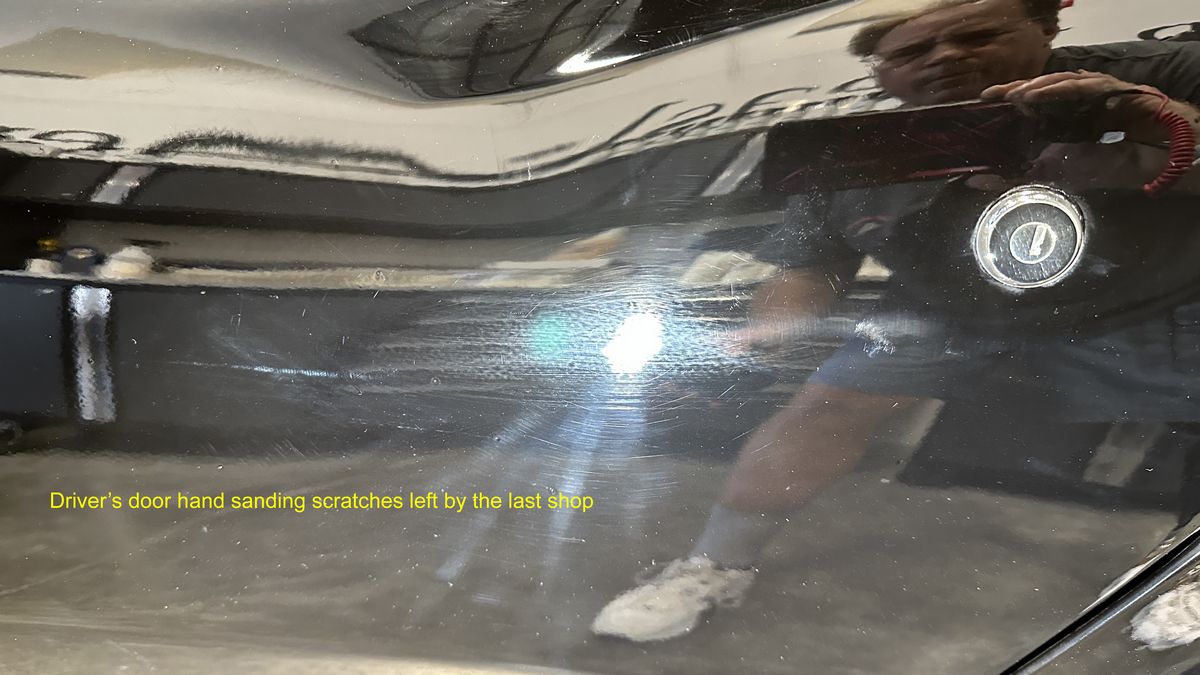

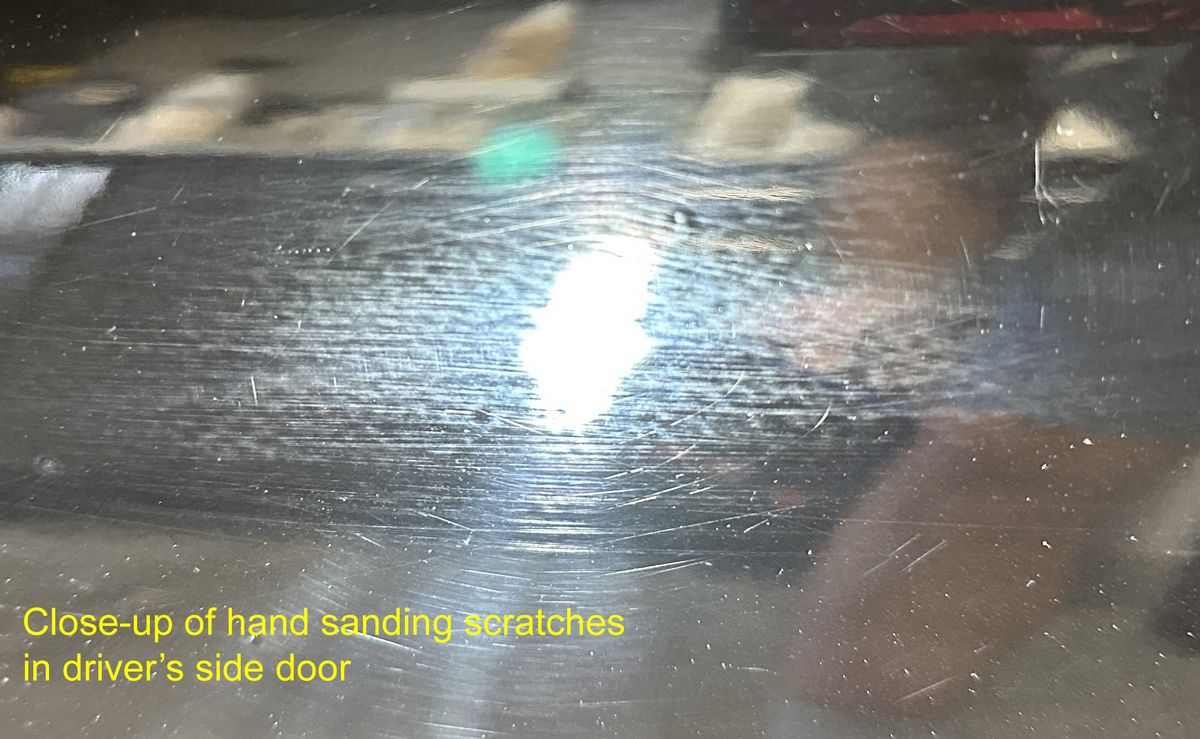

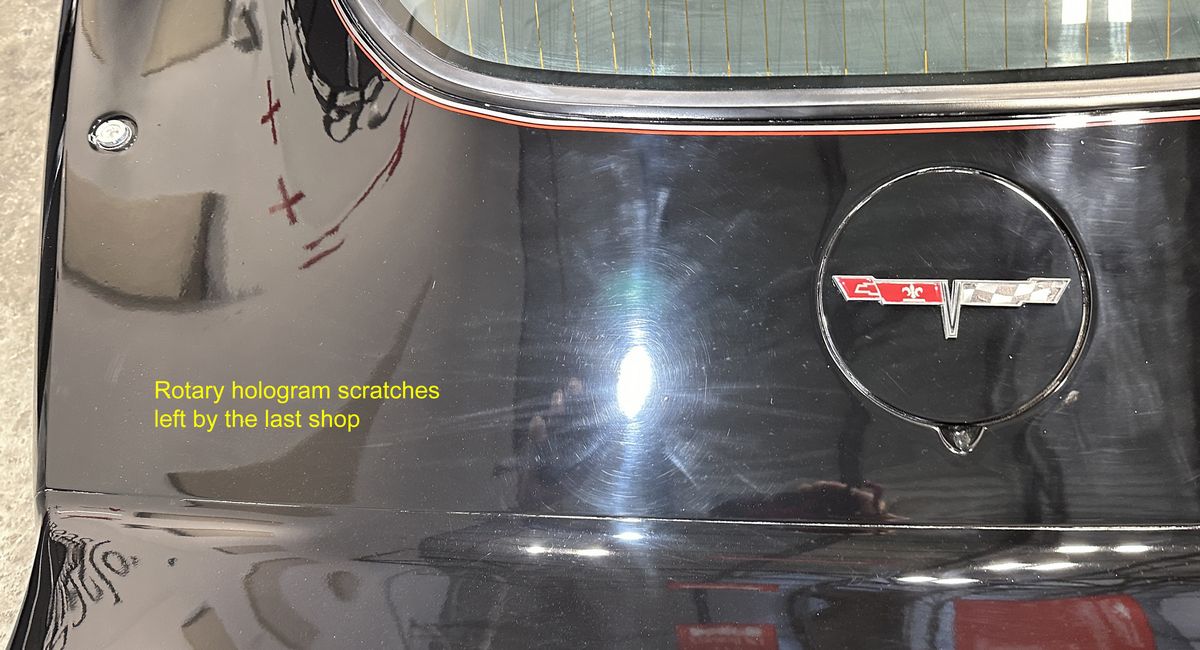

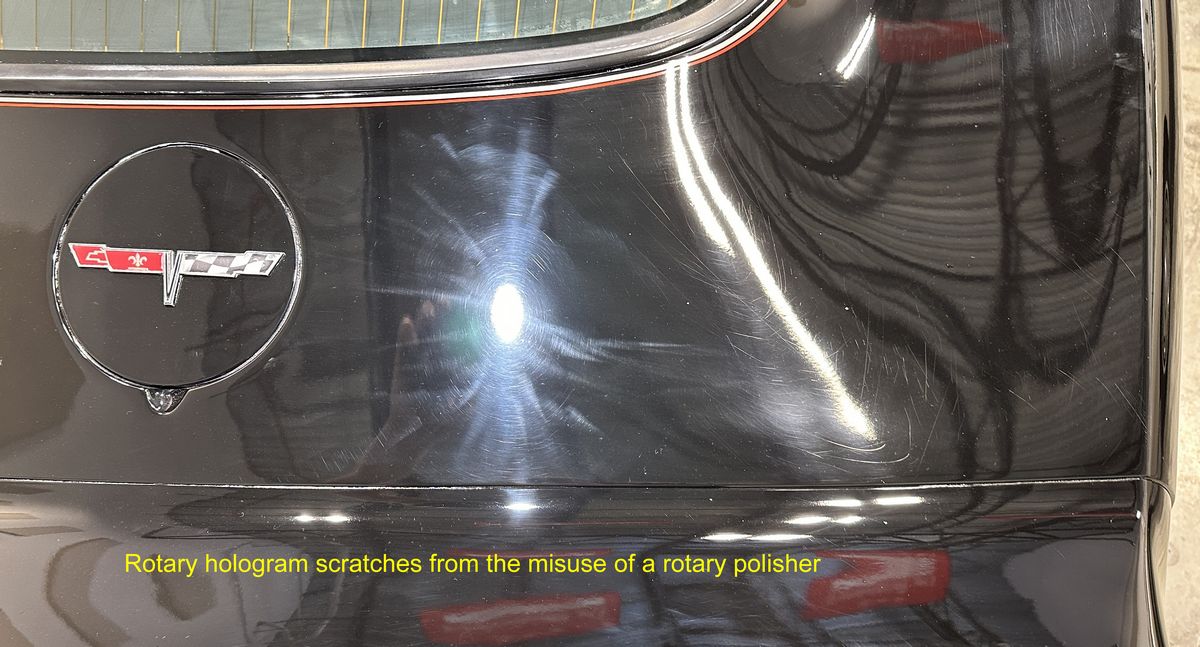

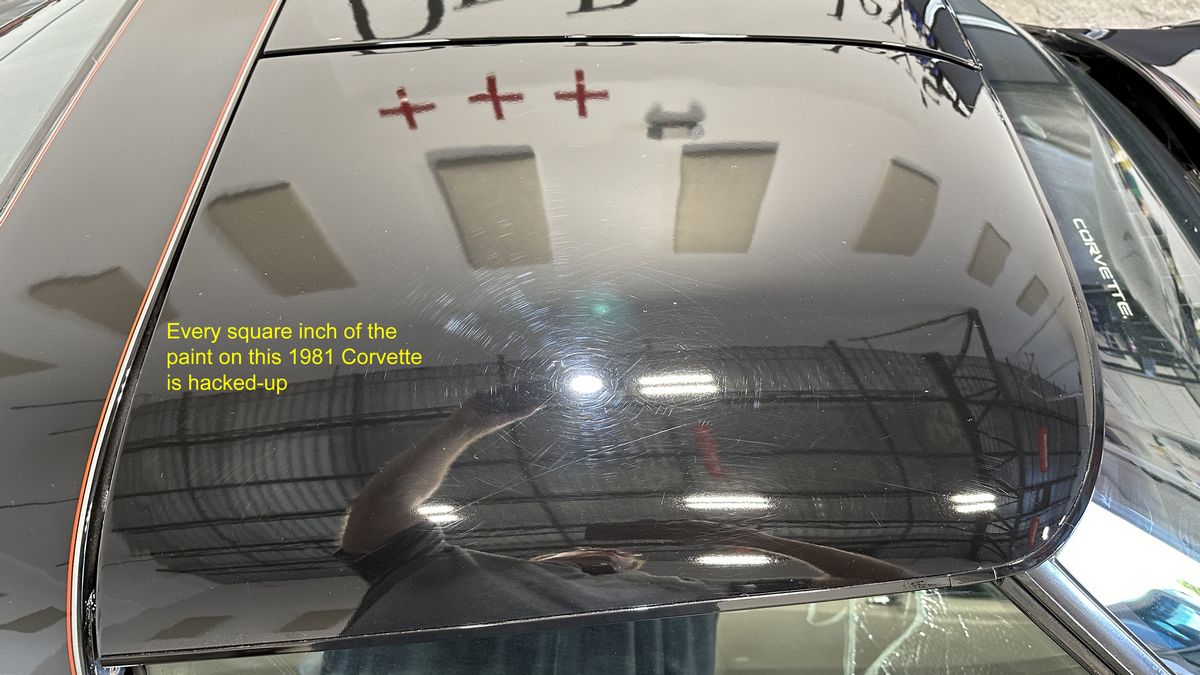

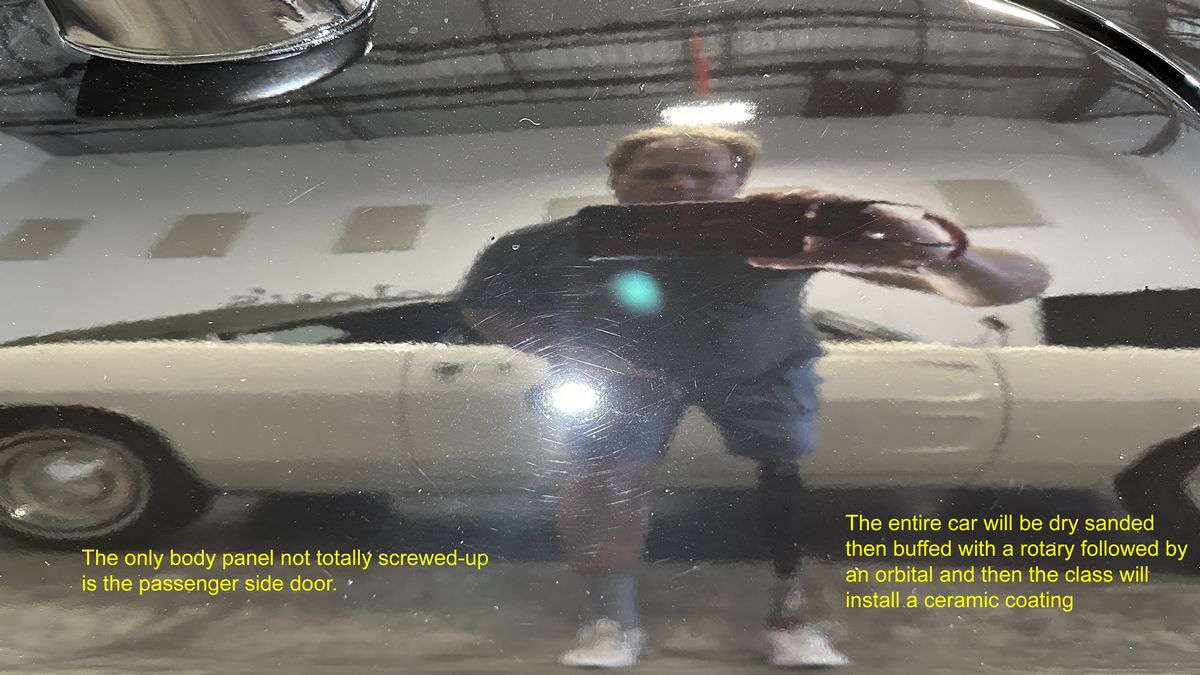

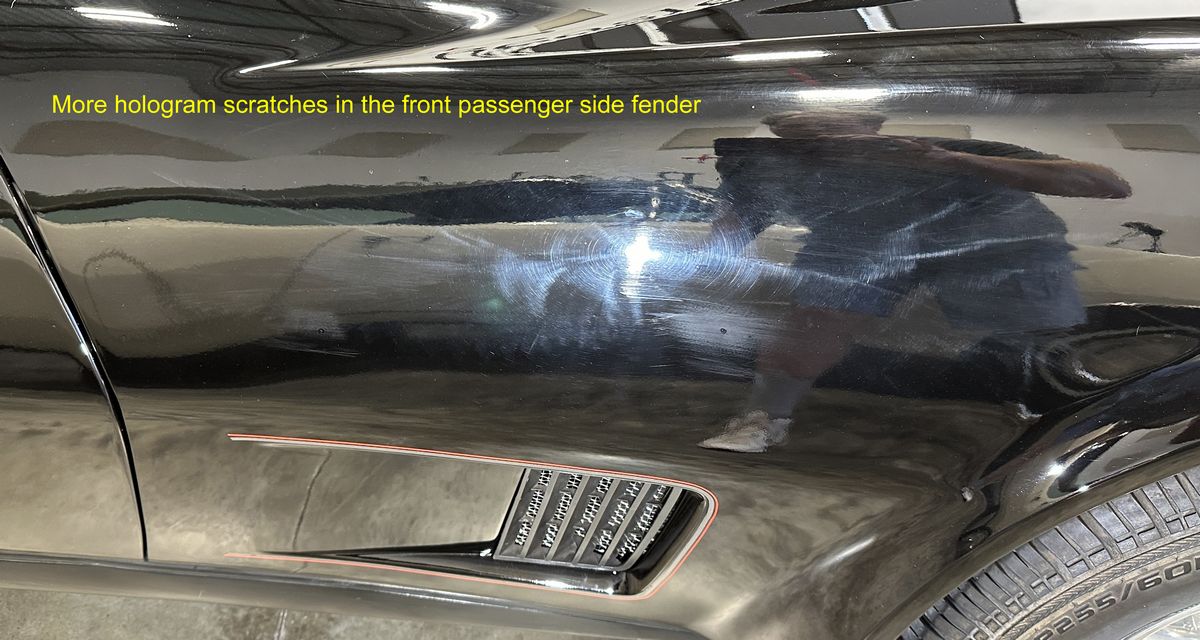

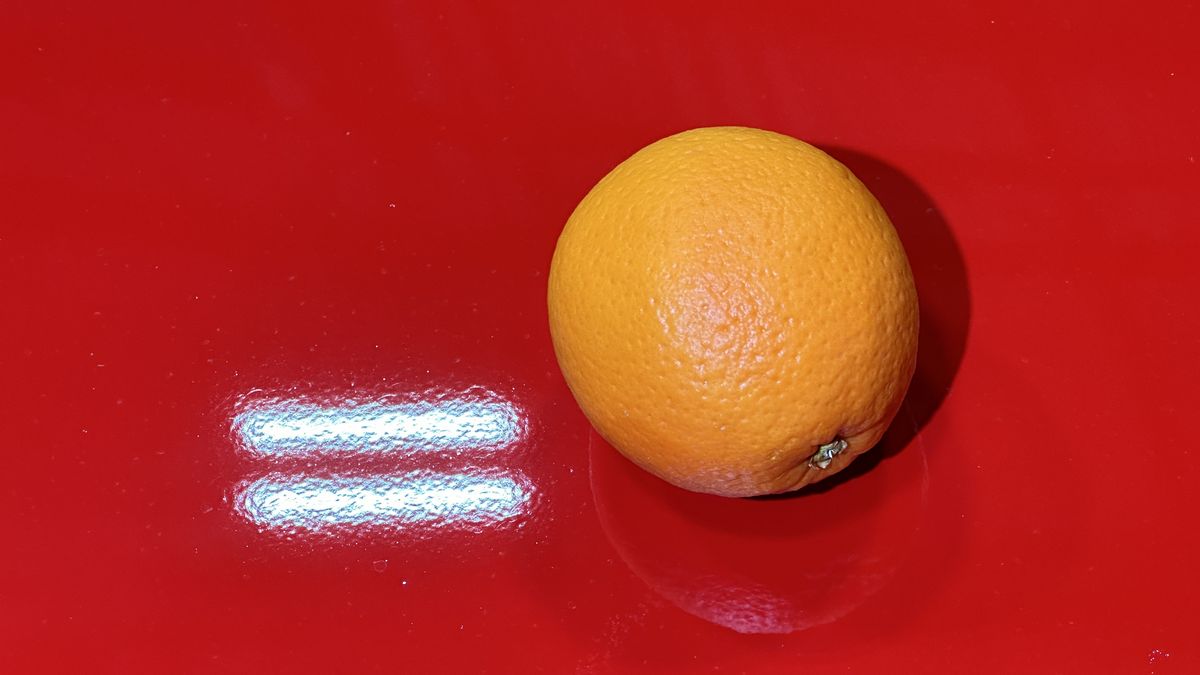

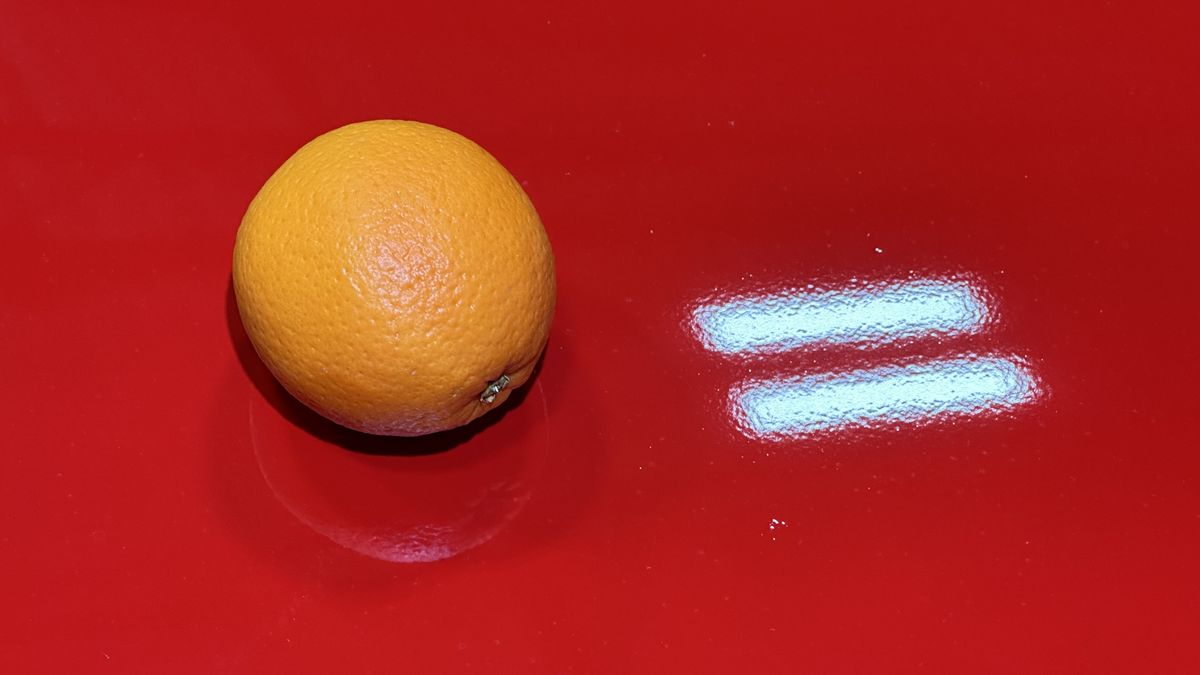

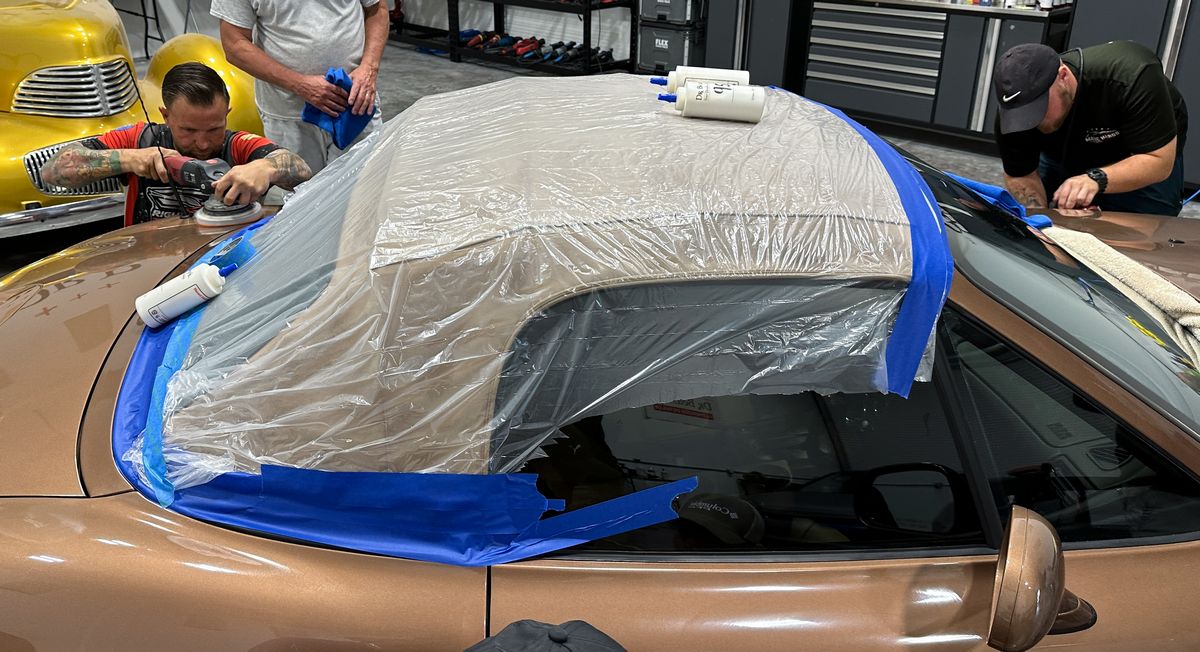

1981 Corvette - Dry sanded by hand and machine - ceramic coated.

1931 Model A Streetrod - Machine dry sanded & ceramic coated.

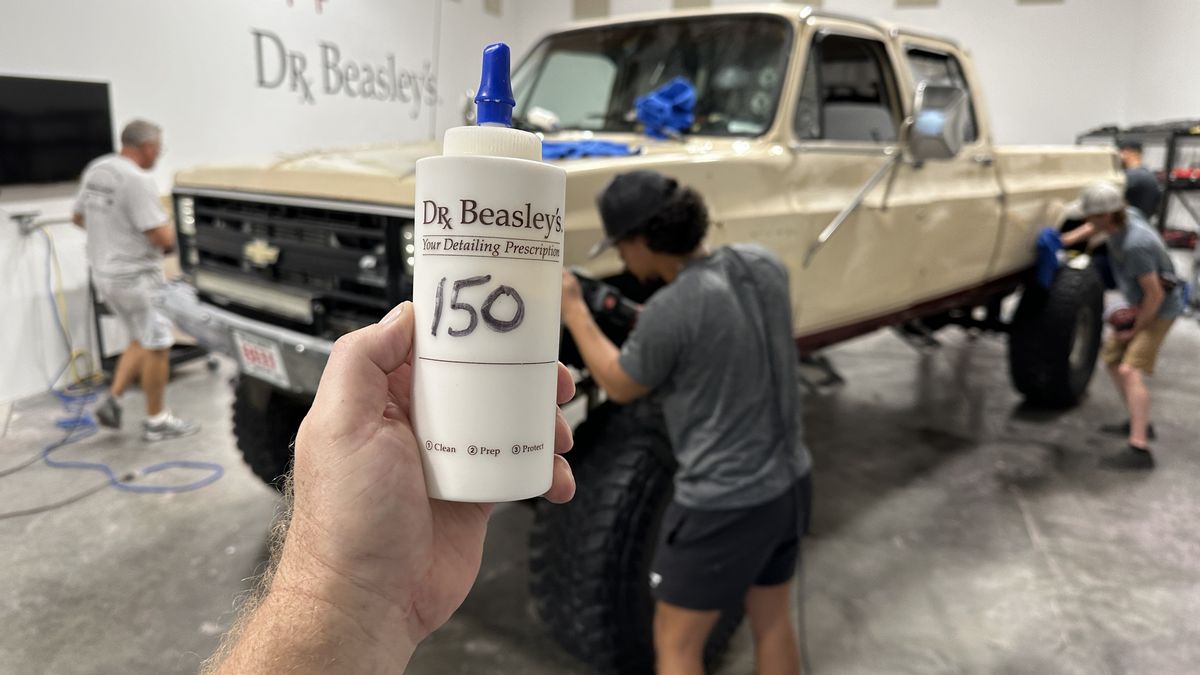

1988 Chevy Crew Cab Monster Truck - Two step paint correction and ceramic coated.

2000 BMW Z3 - One-step paint correction and ceramic coated.

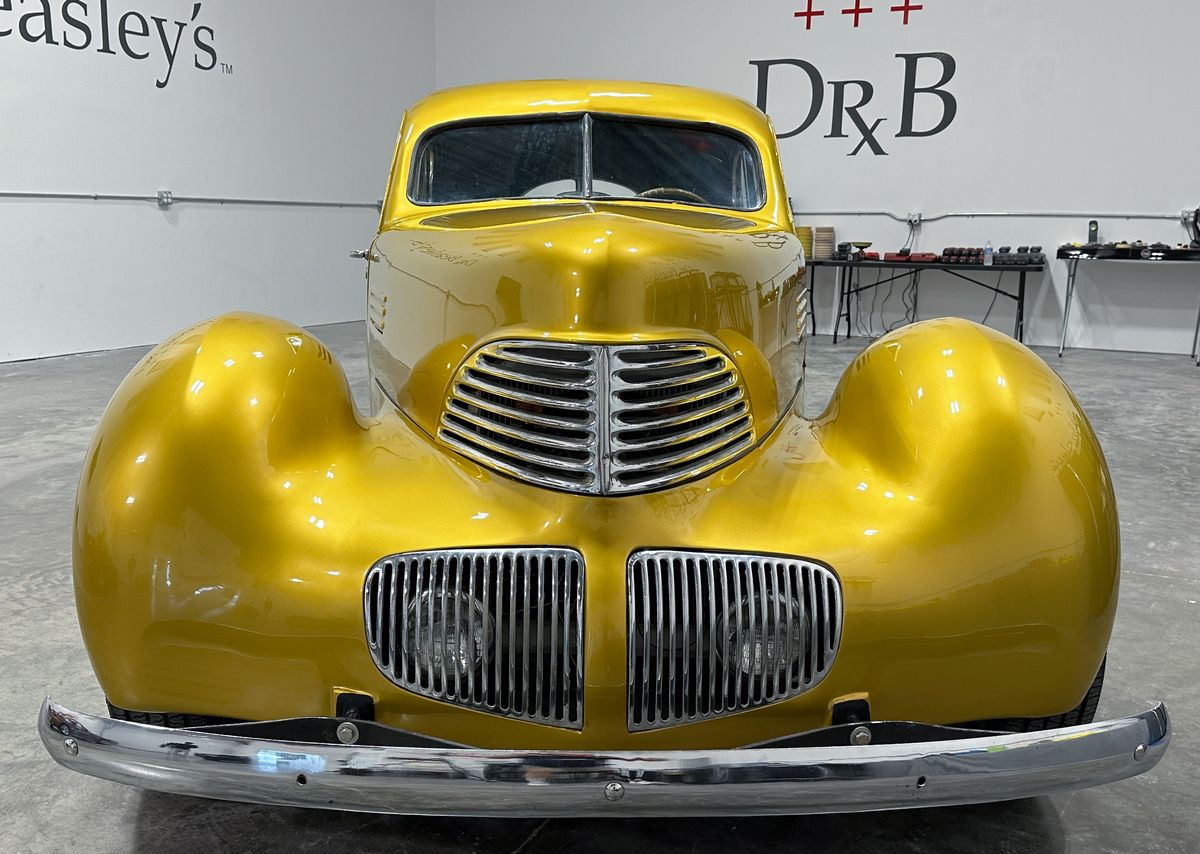

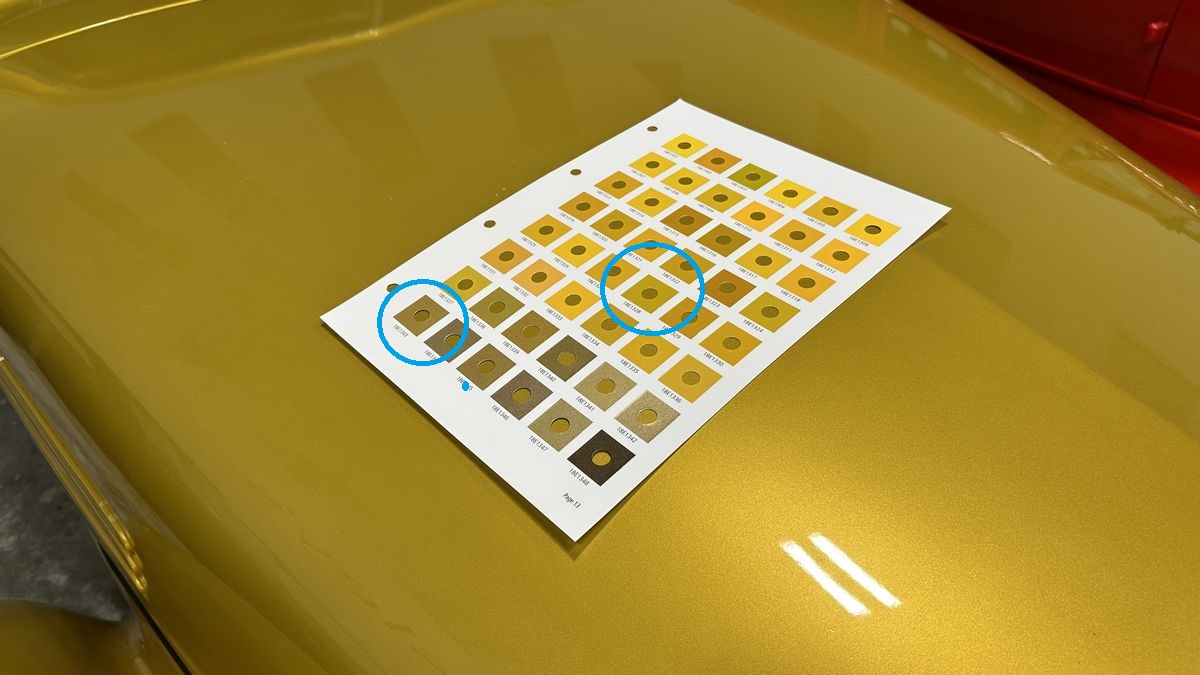

1941 Grahm Hollywood - Machine damp sanded and ceramic coated.

24' Robalo Center Console - Multiple step machine sanding, polishing and ceramic coated.

More pictures showing what our classes look like to be added...

Mike

Congratulations to the May 3-day class! This class detailed 5 unique cars, including sanding 3 of these cars and also sanding, buffing and ceramic coating the 24' Robalo Center Console boat. To get signed up for the next big 3-day class that includes paint correction, ceramic coatings, sanding to remove orange peel and extreme boat detailing!

Click here to sign-up for the September 20th, 21st and 22nd NO chairs 100% hands-on detailing class!

Here's the class that made all the magic happen!

Kaiden

Michael

Tyler

Juan

Edson

Jesus

Shawn

Billy

Cory

Here's the 5 cars this class detailed and the huge center console boat

1981 Corvette - Dry sanded by hand and machine - ceramic coated.

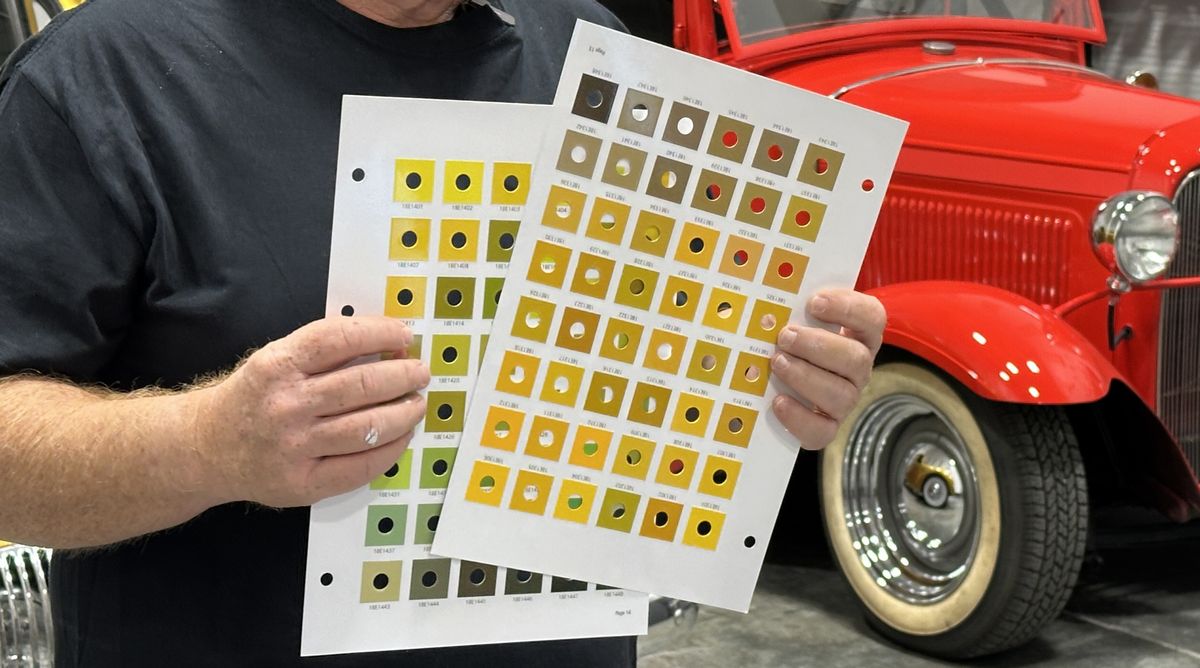

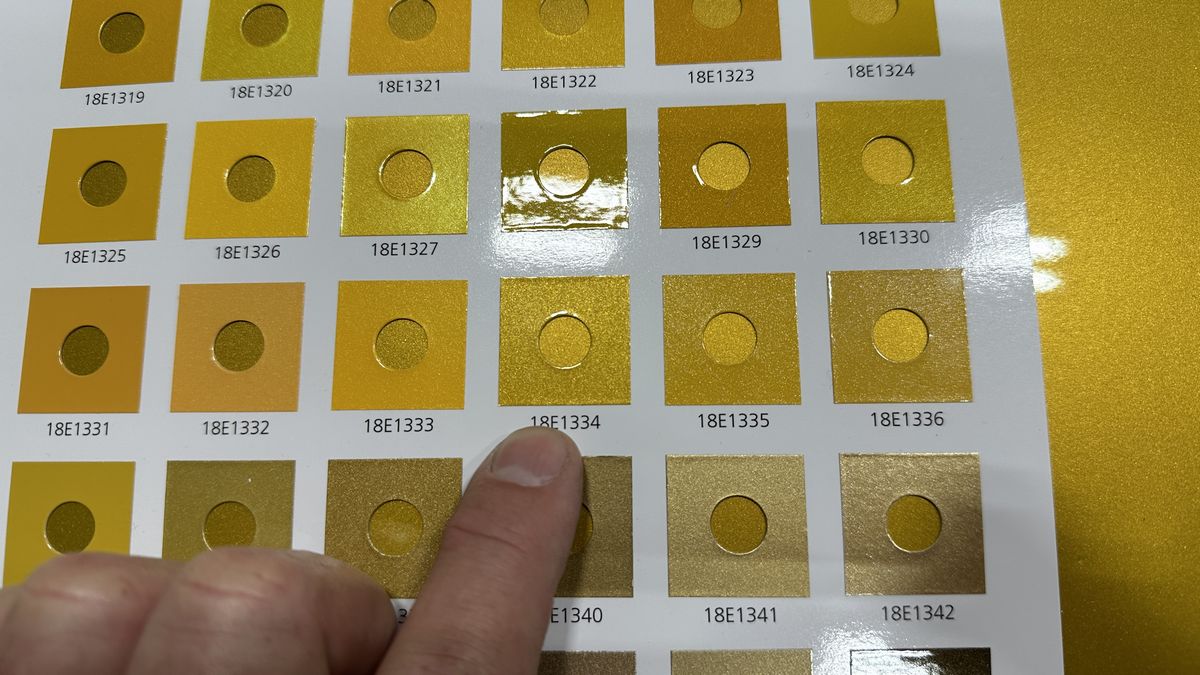

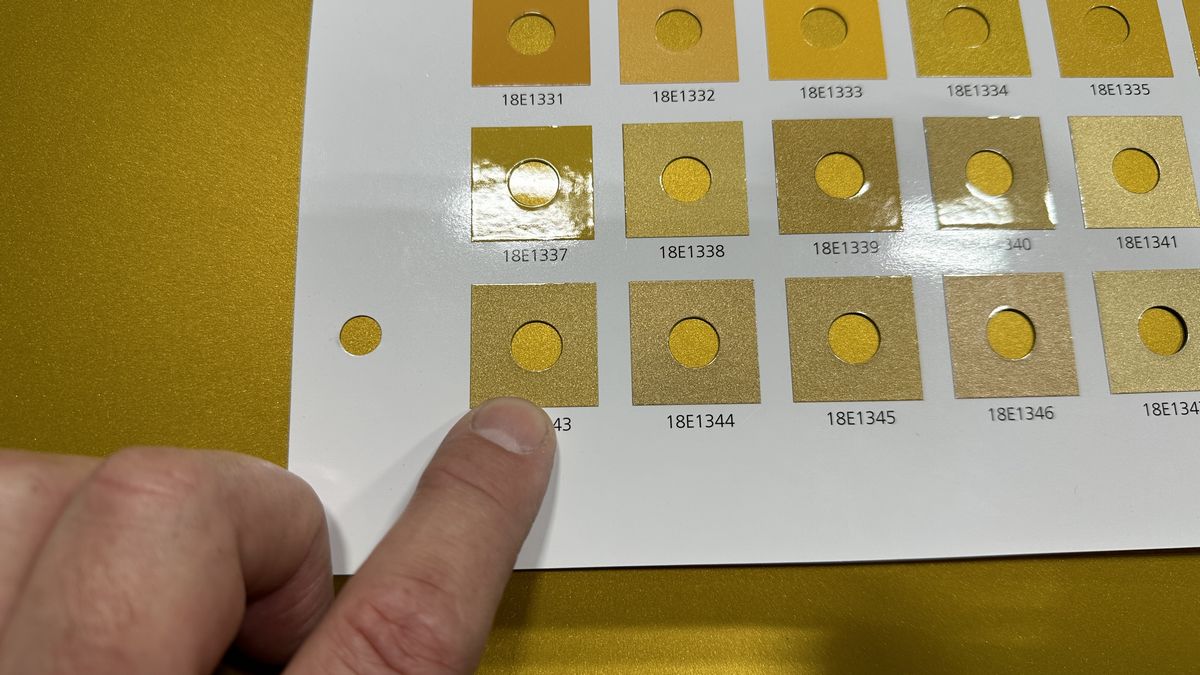

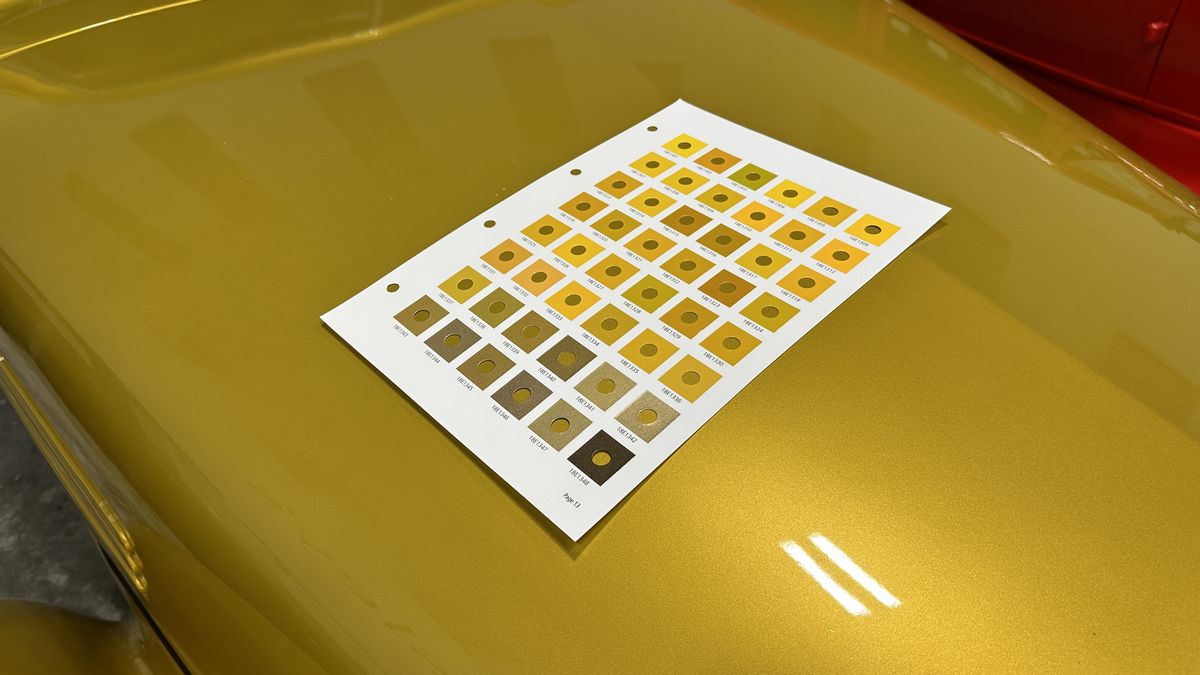

1931 Model A Streetrod - Machine dry sanded & ceramic coated.

1988 Chevy Crew Cab Monster Truck - Two step paint correction and ceramic coated.

2000 BMW Z3 - One-step paint correction and ceramic coated.

1941 Grahm Hollywood - Machine damp sanded and ceramic coated.

24' Robalo Center Console - Multiple step machine sanding, polishing and ceramic coated.

More pictures showing what our classes look like to be added...

Mike

Last edited: