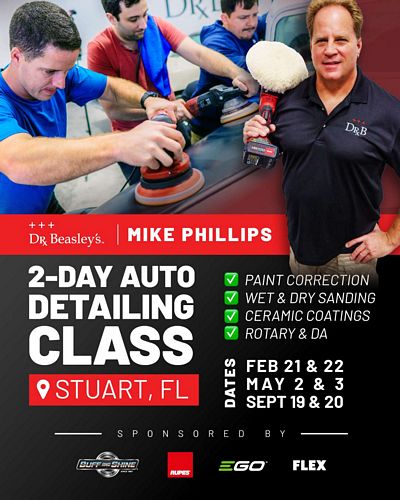

- Admin

- #1

- Joined

- May 21, 2021

- Messages

- 2,531

- Reaction score

- 1,500

- Points

- 113

- Location

- Stuart, Florida

- Website

- themikephillipsforum.com

Review: FLEX PE 14-3 125 Rotary Polisher by Mike Phillips

First thank you to Chris Metcalf and FLEX Tools for their trust and appreciation for the work I do to showcase FLEX tools. Received a package from FLEX, inside is the new FLEX PE 14-3 125 which is the replacement for the older FLEX L3403 VRG Lightweight Rotary Polisher.

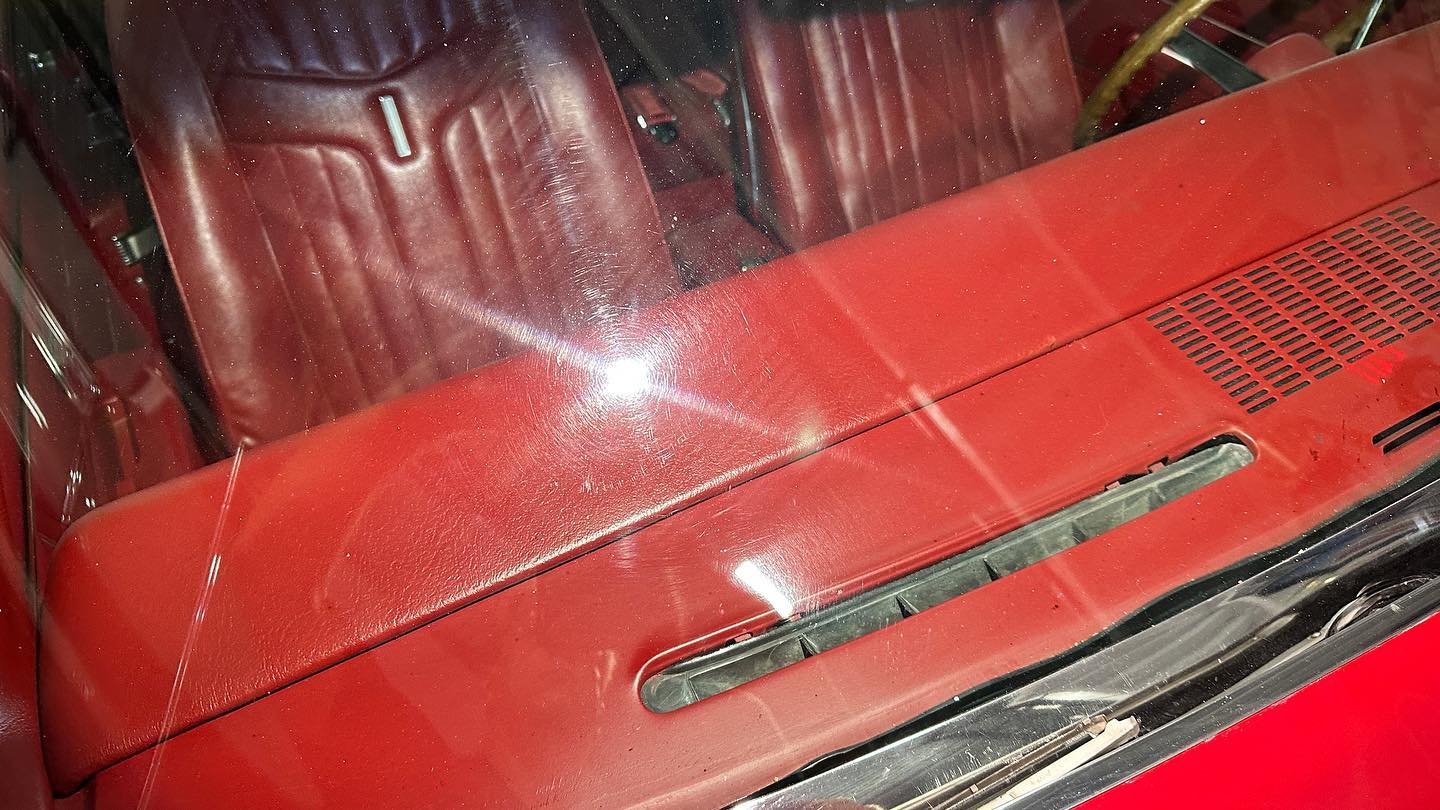

The polisher you see below is actually a proto-type, you can tell by the different colors of red used for the body parts.

Review

If you need a rotary polisher that offers higher RPMs for things like glass polishing, perhaps metal or gelcoat polishing, than this rotary polisher offers a RPM speed range from a low of 1100 RPM to 3700 RPM.

It's quiet, lightweight and compact in size, features that make buffing for extended periods of time a heck of a lot more enjoyable than most rotary polishers. The gears are precision machined stainless steel with exact tolerances so when they mesh during operation there's no growling like less expensive options that use stamped steel gears.

I primarily use this rotary for machine polishing glass as the best speeds for sub-surface glass polishing are above 2500 RPM. I normally use the Cordless FLEX PE-150 Rotary Polisher for doing paint correction and it WILL work for sub-surface glass polishing but the higher RPM of the FLEX PE 14-3 125 Rotary Polisher is a better option.

Plus... it's FLEX quality.

Where to buy?

At this time I don't have a preferred vendor to send people to if they would like to purchase this polisher but behind the scenes I'm working with partnership with a company that I will send all my product recommendations too.

Stay tuned...

Mike Phillips

First thank you to Chris Metcalf and FLEX Tools for their trust and appreciation for the work I do to showcase FLEX tools. Received a package from FLEX, inside is the new FLEX PE 14-3 125 which is the replacement for the older FLEX L3403 VRG Lightweight Rotary Polisher.

The polisher you see below is actually a proto-type, you can tell by the different colors of red used for the body parts.

Review

If you need a rotary polisher that offers higher RPMs for things like glass polishing, perhaps metal or gelcoat polishing, than this rotary polisher offers a RPM speed range from a low of 1100 RPM to 3700 RPM.

It's quiet, lightweight and compact in size, features that make buffing for extended periods of time a heck of a lot more enjoyable than most rotary polishers. The gears are precision machined stainless steel with exact tolerances so when they mesh during operation there's no growling like less expensive options that use stamped steel gears.

I primarily use this rotary for machine polishing glass as the best speeds for sub-surface glass polishing are above 2500 RPM. I normally use the Cordless FLEX PE-150 Rotary Polisher for doing paint correction and it WILL work for sub-surface glass polishing but the higher RPM of the FLEX PE 14-3 125 Rotary Polisher is a better option.

Plus... it's FLEX quality.

Where to buy?

At this time I don't have a preferred vendor to send people to if they would like to purchase this polisher but behind the scenes I'm working with partnership with a company that I will send all my product recommendations too.

Stay tuned...

Mike Phillips