- Admin

- #1

- Joined

- May 21, 2021

- Messages

- 2,021

- Reaction score

- 1,109

- Points

- 113

- Location

- Stuart, Florida

- Website

- themikephillipsforum.com

Hologram free using only a rotary polisher?

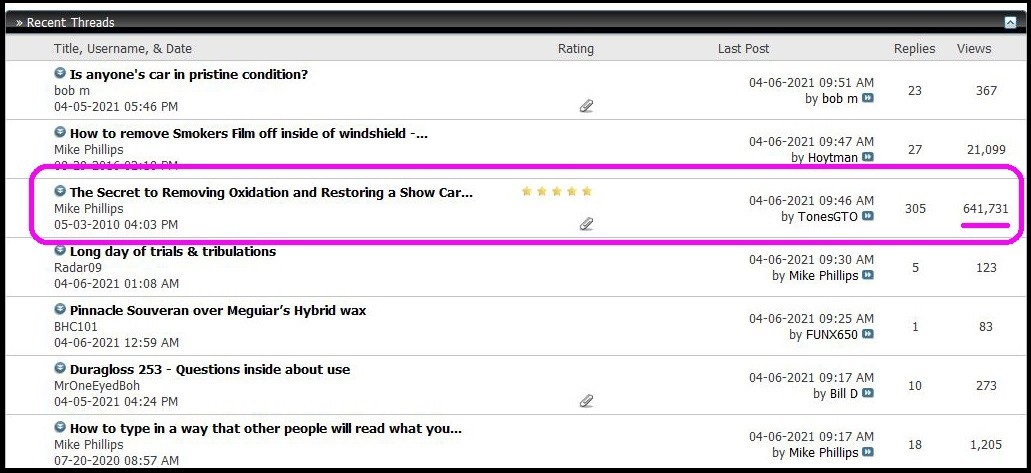

I've been in a great discussion with Bill G about using rotary polishers with the end-goal of finishing out hologram free. Bill started by discussing this topic with me via email but as most of you know, I MUCH prefer to hold discussions, especially deep discussion on a forum. With email, 2 sets of eyeballs see the discussion. On a forum, potentially tens of thousands of people will see the discussion. My original article on the geek forum about how to restore antique, original single stage paint had, 641,731 views

And that was back in April of 2021 when I took the below screenshot.

I'm sad to say, Autogeek has done what's called a "Soft Delete" of all my how to articles? I emailed the Admin last week asking if they would undo the soft delete but I've never heard back from them. What a Soft Delete means is, the articles are still there, they are just invisible when you visually LOOK for them in the forum group. Here's the forum group where I have over 700 how-to articles.

How to Articles

If you type the right key words into Google, you can find my how-to articles, but if you LOOK for them, they are invisible. Now why would Autogeek want to do this?

My bigger picture point being, discussing car detailing in email works, but tens of thousands or over a half million people according to the stats above, can see, read and participate in a discussion on a forum but not in an email. Make sense?

So here's the conversation about holograms and rotary polishers.

And here's where we're at as of this morning, Monday, April 17th, 2023, when I asked Bill if it would be okay to move this discussion to the forum and he politely said "yes".

I can only share my experience, and what I've seen is when using small pads on rotary tool on dark paint, you will tend to leave a visible hologram in the paint. I think you are more able to finish out hologram-free with larger pads than smaller pads, I'm not sure if I can use a keyboard to verbalize why?

The ability to finish out hologram-free using ONLY a rotary polisher comes down to at least 2 factors.

1: Paint type - some paint is more polishable than other paints.

2: Abrasive technology - as most reading this and anything I've ever written or said in a video or detailing class - the MOST IMPORTANT FACTOR when it comes to polishing paint is NOT the person, the tool or the pad, it's the stuff that's touching the paint - the abrasive technology. And I "guess" some people in the car detailign world think that all abrasive technology is the same or unimportant but I'm here to tell you that "yes" even in the year 2023 - there is still low tech abrasive technology on the market.

Yes you are correct. Some paint is hard, some paint is soft, some paint is right in the middle of the paint hardness/softness spectrum, where we all like it. And I would say some paint, simply due to the resin chemistry, is more polishable than other paints, or another way to say this would be, some paints are NOT as polishable than other paints. I believe someone at RUPES, could be my long-time friend Jason Rose, coined the term Sticky Paint, which is a paint that is both soft and more difficult to polish.

So "yes" paints are different and if a person buffs out enough cars they will discover this sooner or later.

Thank you for reaching out to me with your questions, I always appreciate anyone that values my opinion and/or feedback enough to contact me and ask questions. I hope I've been able to share at least my take on this subject of finishign out hologram-free using only a rotary polisehrs.

And to also share my opinion on this topic, here's what I think, share and practice.

Even if you can finish out hologram-free using only a rotary polisher, why risk it? By this I mean, because most people can't and/or don't know how to chemically strip the paint and then use strong light to inspect the results to ENSURE the paint is in fact hologram-free, why risk it? Instead, use ANY brand of orbital polisher, either gear-driven or free spinning for your last machine polishing step and take comfort knowing if you're using great abrasive technology that the oscillating action of the tool will work-out the hologram scratches and leave a more perfect finish that will hold up to strong, bright light over time.

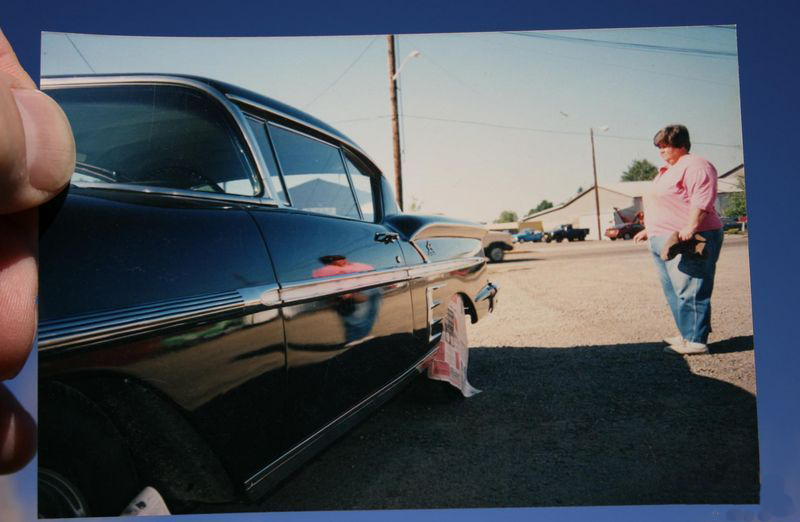

Again, just my take on the topic after being burned one time a long time ago before all these orbital polishers some take for granted were even invented. Here's the car and the owner that burned me.

1958 Chevy Bel Air

The lady in the picturte is the wife of the guy that built the car. The car was painted a Black Cherry Metallic.

Mike Phillips

I've been in a great discussion with Bill G about using rotary polishers with the end-goal of finishing out hologram free. Bill started by discussing this topic with me via email but as most of you know, I MUCH prefer to hold discussions, especially deep discussion on a forum. With email, 2 sets of eyeballs see the discussion. On a forum, potentially tens of thousands of people will see the discussion. My original article on the geek forum about how to restore antique, original single stage paint had, 641,731 views

And that was back in April of 2021 when I took the below screenshot.

I'm sad to say, Autogeek has done what's called a "Soft Delete" of all my how to articles? I emailed the Admin last week asking if they would undo the soft delete but I've never heard back from them. What a Soft Delete means is, the articles are still there, they are just invisible when you visually LOOK for them in the forum group. Here's the forum group where I have over 700 how-to articles.

How to Articles

If you type the right key words into Google, you can find my how-to articles, but if you LOOK for them, they are invisible. Now why would Autogeek want to do this?

My bigger picture point being, discussing car detailing in email works, but tens of thousands or over a half million people according to the stats above, can see, read and participate in a discussion on a forum but not in an email. Make sense?

So here's the conversation about holograms and rotary polishers.

Bill G said:Mike,

I have been a fan of much of your historical comments in the AG forum over the last 6 years and I remember coming across a lengthy comment you had on why it is nearly impossible to finish a correction with a rotary, that anyone who claims they can do it flawlessly is lying (essentially). However, I came across a few YouTube videos of Yvan Lacroix making a persuasive argument why all the fear about rotary polishers is BS. That if run at the lowest speed, and without pressure along with a damp pad, it is the best gloss and shine you will get. That D/A's are really for cutting and not finishing down paint the best. That they leave micro marring. I know you prefer to answer in your forum, but I haven't signed up yet (plan on doing so), so if you would kindly answer in my email or to your new AF forum, I would greatly appreciate it.

Regards,

Bill

Mike Phillips said:Hi Bill,

What I always say about finishing with a rotary only is this,

It’s not about the person, the pad or the product – it’s about the PAINT. Instead of risking leaving holograms behind, (because you can’t see them in the moment), eliminate the risk and simply finish down with any dual action polisher.

As you know, paint is different and always changing. Some paint is more polishable than others. I would never try to change Yvan’s opinion – that’s him and his experience. Me? I’ve had different experience over the decades.

By the way, here’s a car I detailed using ONLY a rotary buffer from back in 2011 - the picture below were me showing the final results outside in full overhead sun. It was a tick cloudy that day, something I have no control over, but I did move the car outside and take pictures to show no holograms. These pictures can be found on page 7 of the thread, which was a review of the NEW (at that time), DeWALT 849X.

Bumblebee - Testing out the NEW DeWALT DWP849X

And if you read the entire thread, I talk about how most people that say they can finish with only a rotary never prove it. In the article, I prove it by pulling the car out into high overhead sunlight and take pictures.

That’s the thing about “claiming” you can finish down hologram free – most people never prove it. They state it like a boss, but never prove it. The only way to prove it is to chemically strip the paint and then either move the car into bright, full-on overhead sunlight or use a strong swirl finder light.

I never see anyone prove it.

Mike

Bill G said:Thanks Mike, your quick response is greatly appreciated.

I need to rethink my idea of purchasing a rotary at this point. Back to square one. I have a D/A but not a forced rotation so I was thinking of getting the Flex 10-8 125 Supa Beast until I saw Yvan's videos. I need to find a place to try it out first it seems. All you guys are in the southeast and we never get a chance to go to mobile classes here in San Diego, otherwise I would have done that by now. As a 993TT owner that I bought new, I really became more interested in the aspects of detailing about 10 years ago. So I have limited time with polishing, especially paint correction given you can't do it much on any given vehicle. But since I peaked my interest tending to my 1997 Turbo, I have expanded to my daily drivers and looking for better tools in the process. It appears I need to think this through better and/or try to find a place to use both first.

BTW, it has been great watching all your videos and reading your forums. Would be nice to have 1/100th of your skill set. Wishing you the best at Autoforge, it appears to have been a great move for you.

Regards,

Bill

Mike Phillips said:Hi Bill,

I love the rotary but from what I can tell, you would be much better served with the FLEX Supa BEAST. This is the tool I used this last weekend on the 1967 Ferrari. I strongly recommend getting the optional 6” backing plate and then take a look at the 6.75 foam pads I linked to in my article. They work GREAT on this tool and this size backing plate.

I think FLEX made a mistake when they packaged the CBEAST and the Supa BEAST with the factory 5” backing plate. These tools have a LOT of power and the larger backing plate enables you to take advantage of the power. The 5” doesn’t let you take advantage of the backing plate. Also – larger footprint pads make your buffing experience much smoother – this makes using the tool so much more enjoyable.

1967 Ferrari 275GTB/4 NART Spider detailed by Mike Phillips at AutoForge.net

Mike

And here's where we're at as of this morning, Monday, April 17th, 2023, when I asked Bill if it would be okay to move this discussion to the forum and he politely said "yes".

Bill G said:Hi Mike,

One last question for you. I have the Flex PXE 80 and I usually only use it for small areas with the D/A 3" head. So, this morning I put on the rotary spindle with a 2" black pad and fine polish just to see if in a small area I could replicate Yvan's approach to polishing with a rotary. I put it on speed 1 as he suggested, held it very lightly and just guided the polisher, and while I did better than I ever have, I couldn't get it completely hologram free. I did this on my black Model S so it was very easy to see my outcome with a swirl light.

So my question is:

With such a small pad is there a difference in difficulty getting a rotary action to finish out with a small pad vs the 14-2 150 with a black 6" waffle pad as Yvan was using?

Or would it be just as difficult, and I have no business (at this point) owning this tool?

As you suggested, I am inclined to go with the Supa Beast as my finishing polisher after this attempt, but just wanted to know if there is a difference with such a small pad. I know Yvan has 40 years of experience and it is foolish to compare my knowledge and ability with his or yours, which I am not, but just to satisfy my curiosity I would like to know. And when I say, just as difficult, I mean for someone who hasn't taken any instruction before, but just have done reasonably well with a basic D/A (PC) since 2017. He just made it look so damn easy and it would be hard to screw it up, so I figured buying the tool and using it for my final polishing (which I mostly do as I take great care for my cars and that is all they really ever need) would be a great option.

I can only share my experience, and what I've seen is when using small pads on rotary tool on dark paint, you will tend to leave a visible hologram in the paint. I think you are more able to finish out hologram-free with larger pads than smaller pads, I'm not sure if I can use a keyboard to verbalize why?

The ability to finish out hologram-free using ONLY a rotary polisher comes down to at least 2 factors.

1: Paint type - some paint is more polishable than other paints.

2: Abrasive technology - as most reading this and anything I've ever written or said in a video or detailing class - the MOST IMPORTANT FACTOR when it comes to polishing paint is NOT the person, the tool or the pad, it's the stuff that's touching the paint - the abrasive technology. And I "guess" some people in the car detailign world think that all abrasive technology is the same or unimportant but I'm here to tell you that "yes" even in the year 2023 - there is still low tech abrasive technology on the market.

Bill G said:One last question if I may. It seems like Tesla has very soft paint and highly susceptible to scratching, vs say, my Range Rover that seems quite hard and applied extremely well. Am I correct on that?

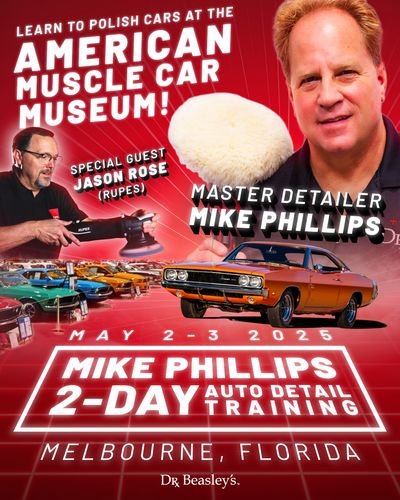

Yes you are correct. Some paint is hard, some paint is soft, some paint is right in the middle of the paint hardness/softness spectrum, where we all like it. And I would say some paint, simply due to the resin chemistry, is more polishable than other paints, or another way to say this would be, some paints are NOT as polishable than other paints. I believe someone at RUPES, could be my long-time friend Jason Rose, coined the term Sticky Paint, which is a paint that is both soft and more difficult to polish.

So "yes" paints are different and if a person buffs out enough cars they will discover this sooner or later.

Bill G said:I may be moving back to the east coast this year and will find myself spending time in Florida in the winter. If I make the move, I am definitely going to sign up for your classes.

I know you are extremely busy and am grateful you have taken the time to help out.

Regards,

Bill

Thank you for reaching out to me with your questions, I always appreciate anyone that values my opinion and/or feedback enough to contact me and ask questions. I hope I've been able to share at least my take on this subject of finishign out hologram-free using only a rotary polisehrs.

And to also share my opinion on this topic, here's what I think, share and practice.

Even if you can finish out hologram-free using only a rotary polisher, why risk it? By this I mean, because most people can't and/or don't know how to chemically strip the paint and then use strong light to inspect the results to ENSURE the paint is in fact hologram-free, why risk it? Instead, use ANY brand of orbital polisher, either gear-driven or free spinning for your last machine polishing step and take comfort knowing if you're using great abrasive technology that the oscillating action of the tool will work-out the hologram scratches and leave a more perfect finish that will hold up to strong, bright light over time.

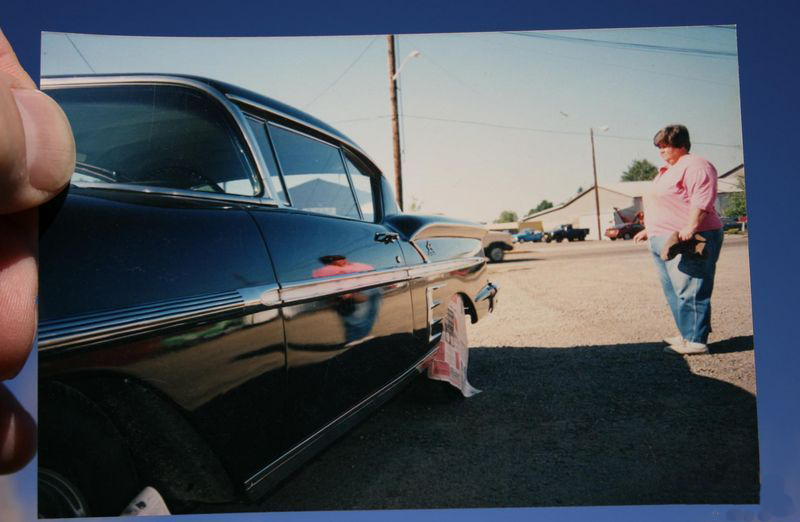

Again, just my take on the topic after being burned one time a long time ago before all these orbital polishers some take for granted were even invented. Here's the car and the owner that burned me.

1958 Chevy Bel Air

The lady in the picturte is the wife of the guy that built the car. The car was painted a Black Cherry Metallic.

Mike Phillips